[ad_1]

The carbon materials graphene has no well-defined thickness; it merely consists of 1 single layer of atoms. It’s subsequently sometimes called a “two-dimensional materials.” Attempting to make a three-dimensional construction out of it might sound contradictory at first, but it surely is a crucial objective: if the properties of the graphene layer are to be exploited finest, then as a lot energetic floor space as potential should be built-in inside a restricted quantity.

One of the best ways to realize this objective is to provide graphene on advanced branched nanostructures. That is precisely what a cooperation between CNR Nano in Pisa, TU Wien (Vienna) and the College of Antwerp has now achieved. This might assist, for instance, to extend the storage functionality per quantity for hydrogen or to construct chemical sensors with greater sensitivity.

From strong to porous

In Prof. Ulrich Schmid’s group (Institute for Sensor and Actuator Methods, TU Wien), analysis has been performed for years on easy methods to rework strong supplies reminiscent of silicon carbide into extraordinarily superb, porous constructions in a exactly managed method. “If you happen to can management the porosity, then many alternative materials properties might be influenced consequently,” explains Georg Pfusterschmied, one of many authors of the present paper.

The technological procedures required to realize this objective are difficult: “It’s an electrochemical course of that consists of a number of steps,” says Markus Leitgeb, a chemist who additionally works in Ulrich Schmid’s analysis group at TU Wien. “We work with very particular etching options, and apply tailor-made electrical present traits together with UV irradiation.” This permits to etch tiny holes and channels into sure supplies.

Due to this experience within the realization of porous constructions, Stefan Heun’s staff from the Nanoscience Institute of the Italian Nationwide Analysis Council CNR turned to their colleagues at TU Wien. The Pisa staff was in search of a way to provide graphene surfaces in branched nanostructures to allow bigger graphene floor areas. And the know-how developed at TU Wien is completely fitted to this activity.

“The beginning materials is silicon carbide—a crystal of silicon and carbon,” says Stefano Veronesi who carried out the graphene progress at CNR Nano in Pisa. “If you happen to warmth this materials, the silicon evaporates, the carbon stays and when you do it proper, it could possibly kind a graphene layer on the floor.”

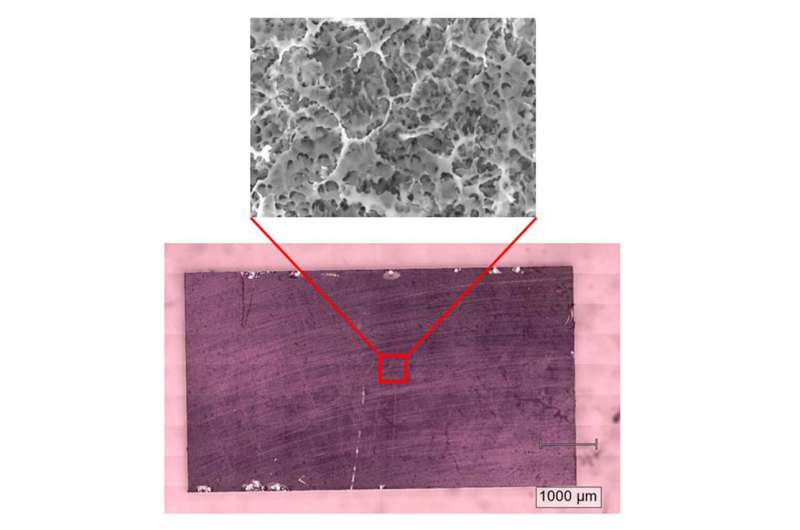

An electrochemical etching course of was subsequently developed at TU Wien that turns strong silicon carbide into the specified porous nanostructure. About 42 % of the amount is eliminated on this course of. The remaining nanostructure was then heated in excessive vacuum in Pisa in order that graphene shaped on the floor. The outcome was then examined intimately in Antwerp. This revealed the success of the brand new course of: certainly, a lot of graphene flakes kind on the intricately formed floor of the 3-D nanostructure.

Lots of floor space in a compact kind

“This permits us to make use of some great benefits of graphene far more successfully,” says Ulrich Schmid. “The unique motivation for the analysis mission was to retailer hydrogen: you may briefly retailer hydrogen atoms on graphene surfaces after which use them for numerous processes. The bigger the floor, the bigger the quantity of hydrogen you may retailer.” However there are additionally many different concepts for utilizing such 3-D graphene constructions. A big floor space can also be a decisive benefit in chemical sensors, which, for instance, can be utilized to detect uncommon substances in gasses.

The analysis was revealed in Carbon.

Stefano Veronesi et al, 3D association of epitaxial graphene conformally grown on porousified crystalline SiC, Carbon (2021). DOI: 10.1016/j.carbon.2021.12.042

Quotation:

2D materials in three dimensions (2022, January 31)

retrieved 31 January 2022

from https://phys.org/information/2022-01-Second-material-dimensions.html

This doc is topic to copyright. Aside from any honest dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for data functions solely.

[ad_2]