[ad_1]

LCDs stands out as the mainstay of shopper shows, however relating to image high quality, together with excessive distinction ratio, brighter colours, and wider viewing angles, OLEDs have the sting. These natural light-emitting diode shows are so-called due to their self-emission capabilities, utilizing natural carbon-based compounds and different components to create colours. As a result of every pixel produces its personal mild, OLEDs require no backlighting. They’re, due to this fact, extra energy environment friendly, and will be fabricated into slimmer and extra versatile shows.

In fact, there’s a catch. OLED shows are costly to fabricate, and conventional fabrication methods want specialised setups. Researchers have been taking a look at 3D-printing options, however even these have had drawbacks, amongst them a scarcity of uniformity within the energetic (emitting) layers of the show.

Current analysis from the College of Minnesota (UM) Twin Cities describes a “one-pot” 3D-printing platform for versatile OLEDs that overcomes a number of the widespread printing issues and simplifies the manufacturing course of. Basically, the researchers mixed all of the essential steps for the manufacturing of the show—extrusion printing of the decrease layers, spray printing of the energetic layers, and structural reconfiguration—right into a single gadget, a custom-built tabletop 3D printer.

“Anybody with the essential information of 3D printing can [print] OLED shows…in houses that possess the right inks and designs.”

—Ruitao Su, MIT

“[Our] printing platform consists of…a high-precision motion-control module, an ink-dispensing module that extrudes or sprays supplies, an imaging system that assists the alignment of gadget layers, and an ink-curing system,” says Ruitao Su, a former Ph.D. scholar on the college, the place he labored on the mission. He’s now a postdoctoral researcher at MIT’s Computational Design and Fabrication Group.

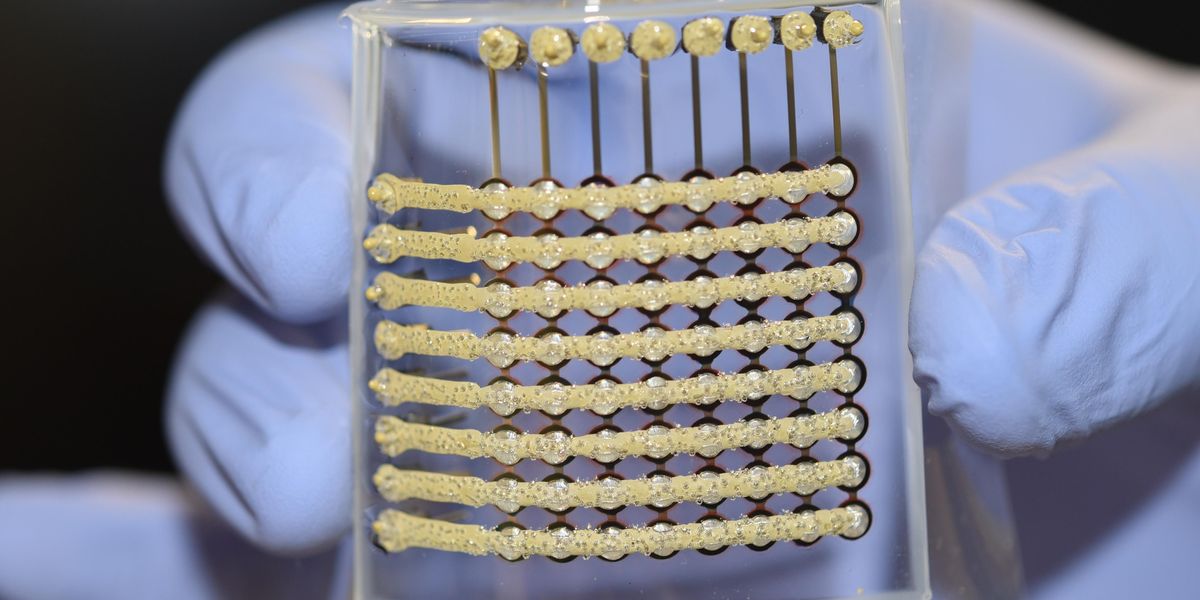

The outcome was a six-layer, 1.5-inch sq. versatile show, during which the electrodes, interconnects, insulation, and encapsulation had been extrusion-printed, whereas the energetic layers had been spray-printed utilizing the identical 3D printer at room temperature. The gadget had 64 pixels, each emitting mild. It was additionally versatile, and the emission remained secure over 2,000 bending cycles.

The key problem printing the energetic or emitting layers, Su says, is attaining a comparatively uniform morphology on the 3D printer. He says his crew at UM solved the issue by producing homogeneous layers of the OLEDs with controllable thickness. One other subject concerned creating secure, room-temperature cathode–polymer junctions. That one, Su says, they solved by growing a mechanical compression course of “that simulates typical metallic forging however performed on 3D printers.”

For Su and his crew, one of many issues in arising with a fabrication course of for a versatile, totally 3D-printed OLED show was price effectiveness. Conventional manufacturing processes require costly microfabrication amenities that need to be housed in clear rooms, he says, however “[in our prototype] the associated fee…is decreased when it comes to the required amenities and specialised personnel.”

Aside from its potential in comfortable electronics and wearables, this “one-pot” methodology permits for different distinctive kind elements past the standard 2D structure. “I envision the direct printing of OLED shows on nonconventional surfaces equivalent to tables, automobiles, and even human our bodies for ubiquitous data show,” says Su.

Such versatile shows could possibly be packaged in an encapsulating materials for all kinds of functions as effectively. “The pixels will be conformally printed on curved surfaces to combine with every day objects within the period of Web of Issues…. The OLED pixels will also be printed in 3D matrices in order that all the printed [device] capabilities as shows.” The group’s print-your-own-display tech might even in the end allow do-it-yourself holograms—although, he says, additional improvements within the {hardware} could be crucial first.

![]()

The phrase “HELLO” was captured whereas the textual content scrolled on the 8-by-8 OLED show.Ruitao Su/College of Minnesota

Despite the fact that their technique was designed for small-batch, custom-made fabrication, Su says, “The purpose is that you simply don’t need to construct a semiconducting manufacturing facility with the intention to have your required units fabricated. As a result of anybody with the essential information of 3D printing can function the machine, the OLED shows theoretically will be printed in houses that possess the right inks and designs.”

Working with versatile OLEDs brings particular challenges too. “[They] require pixels and conductive interconnects that keep good efficiency beneath giant mechanical deformations,” Su explains. “Subsequently, we chosen supplies that maintained excessive electrical conductivities, equivalent to silver-based inks for our electrodes. For the encapsulation, we used a standard clear and versatile polymer, PDMS, to coat the gadget on prime.”

There’s loads of work but to be achieved to enhance this know-how, after all. Higher gadget effectivity and elevated brightness are main challenges for 3D-printed semiconducting units, Su provides, and that’s the place the following focus of this analysis can be.

[ad_2]