[ad_1]

French industrial 3D printer producer AddUp has revealed {that a} new system it has been serving to develop is about to be launched into orbit for testing onboard the Worldwide House Station (ISS).

Working as a part of the European House Company’s (ESA’s) ‘Metal3D’ venture, AddUp has constructed the inner construction and mechanisms of a machine, designed particularly to 3D print metallic components in house. Versus common powder bed-based programs, the demonstrator is alleged to course of wire feedstock affixed to its body, stopping it floating away, and permitting the unit to function in microgravity circumstances.

AddUp’s terrestrial printing portfolio

During the last six years, AddUp has constructed up a portfolio round two of the business’s main metallic 3D printing applied sciences: Powder Mattress Fusion (PBF) and Directed Power Deposition (DED). Within the case of the previous, the agency launched its flagship FormUp 350 system simply final 12 months, a machine designed particularly to fulfill industrial manufacturing challenges resembling security, productiveness and high quality.

Since then, AddUp has put in the FormUp 350 at Ohio State College, the place college students and employees alike have begun engaged on methods to optimize its efficiency. The corporate additionally launched three new course of monitoring packages just lately, to bolster the capabilities of the machine. Composed of AddUp Dashboards, Recoat Monitoring, and Meltpool Monitoring, the suite is designed to supply customers with elevated confidence partially high quality, and unlock the system’s end-use potential.

When it comes to the DED facet of its enterprise, AddUp inherited a lot of its providing from its acquisition of BeAM Machines in June 2018. Nonetheless offered sporting BeAM branding, the agency’s Modulo 250 and Modulo 400 3D printers characteristic barely completely different takes on the expertise, with the previous geared in the direction of R&D purposes, and the latter packing beefed-up specs stated to present it industrial-level capabilities.

Utilizing its vary of DED and PBF machines, almost 40 of which have been put in at its French bases in Strasbourg and Salon de Provence, AddUp continues to hunt out new purposes. Whereas this has beforehand taken the corporate to the periphery of the aerospace sector, and it has developed components resembling warmth exchangers, its ESA venture is now seeing it construct a full-blown orbital 3D printer.

Trialing an orbital metallic 3D printer

Launched by the ESA, with the objective of making the world’s first system able to 3D printing with alloys in orbit, the Metal3D venture will see it work with numerous companions to determine the impression microgravity has on the properties of components produced.

To attain this, the ESA has commissioned the development of two an identical demonstrators, with one being constructed and operated in Toulouse alongside Airbus, and the opposite launched to the ISS’ Columbus module. Naturally, in an effort to enable for an correct evaluation of orbital circumstances on metallic printed elements, the system is being developed to perform each on Earth and in microgravity circumstances.

Different companions tasked with enabling this system to fulfill its aims, embrace a group from Cranfield College, which is overseeing the unit’s vitality and materials supply programs, and Highftech, an R&D specialist that’s in command of taking care of the construct of the machine’s enclosure along with its fluid administration.

For its half within the mission, AddUp has not solely developed a few of the unit’s internals, however the Programmable Logic Controller (PLC) used to regulate it, in addition to the interface that may enable it to speak. Based on AddUp R&D Engineer Alexandre Piaget, the agency additionally performed a key position within the Metal3D’s venture’s pre-planning phases, which “constructed the foundations of what the machine is in the present day.”

“AddUp performs an essential position within the realization of this mission, however its involvement within the venture goes again to the pre-project section the place the feasibility of the venture needed to be demonstrated,” explains Piaget. “Within the ultimate model of the machine, AddUp will probably be in command of the cellular axes, the structural components and the software program of the machine.”

When it comes to the machine itself, it’s stated to be able to overcoming the problems that forestall common 3D printers being utilized in house, i.e. the dangers posed by high-quality powder floating from the construct space. The system accomplishes this through the use of a wire-laser mixture (W-DED) course of, which sees alloys mounted in place, earlier than being laser fused collectively on a desk that’s moved alongside 3 linear axes and 1 rotary axis.

The 3D printer can also be set to be operated below a nitrogen environment, as a method of limiting the oxidation of supplies and decreasing the chance of combustion, plus, on condition that nitrogen is in brief provide on the ISS, the system is fitted with filtering and cooling performance, to restrict consumption and recycle as a lot gasoline as potential.

Although the machine isn’t anticipated to be fired into orbit till February 2023, AddUp has revealed that it’s already growing a machine impressed by Metal3D together with Airbus, which is able to “enable developments on this expertise to proceed.”

These all in favour of discovering out extra concerning the progress of Metal3D can try AddUp’s orbital 3D printing updates through its YouTube channel, and it has dedicated to offering extra of those insights within the weeks and months forward.

The race to 3D print in microgravity

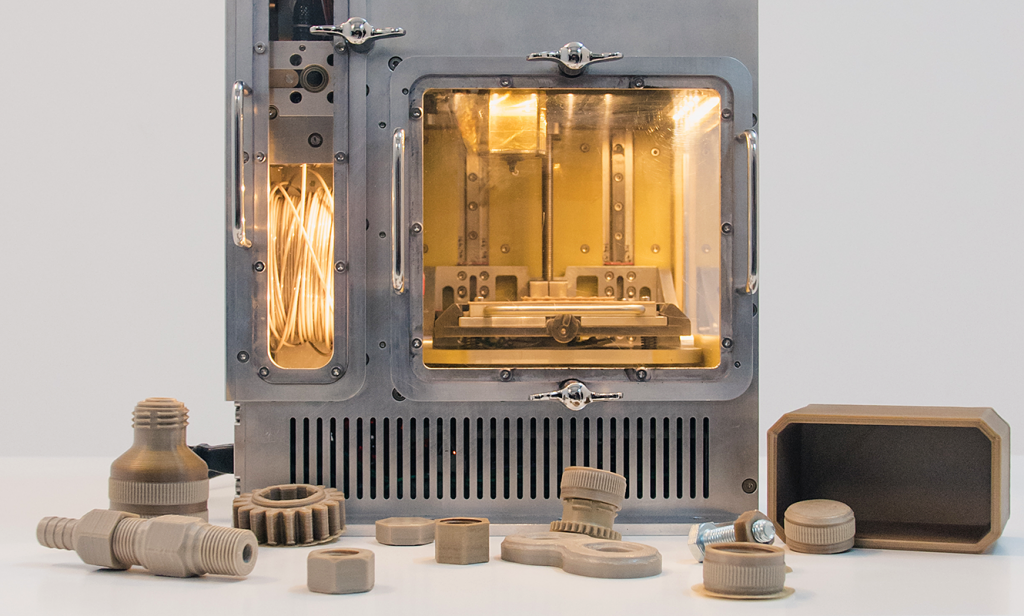

The ISS has turn into a hotbed for 3D printing analysis in recent times, on which each industrial and tutorial researchers have sought to check rising applied sciences below microgravity circumstances. Working alongside one other consortium of companions as a part of ‘Challenge MELT,’ the ESA has beforehand developed a polymer microgravity 3D printer as properly, which was additionally designed for ISS off-world testing.

On the 3D bioprinting entrance, CELLINK partnered with what was Made in House (and is now Redwire) again in 2019, to determine potential orbital bioprinting alternatives onboard the ISS. On the time, it was anticipated that the venture might have a real-world impression on the drug screening and most cancers analysis carried out right here on Earth.

Elsewhere, in a newer experiment carried out by Iowa State College researchers, a novel zero-gravity electronics 3D printer has been examined aboard a refitted airplane. By regularly flying the airplane up and down at 45º angles, the group had been ready (on the high of this curve), to conduct checks whereas experiencing brief bouts of weightlessness in microgravity.

To remain updated with the newest 3D printing information, don’t neglect to subscribe to the 3D Printing Business publication or comply with us on Twitter or liking our web page on Fb.

For a deeper dive into additive manufacturing, now you can subscribe to our Youtube channel, that includes dialogue, debriefs, and pictures of 3D printing in-action.

Are you searching for a job within the additive manufacturing business? Go to 3D Printing Jobs for a choice of roles within the business.

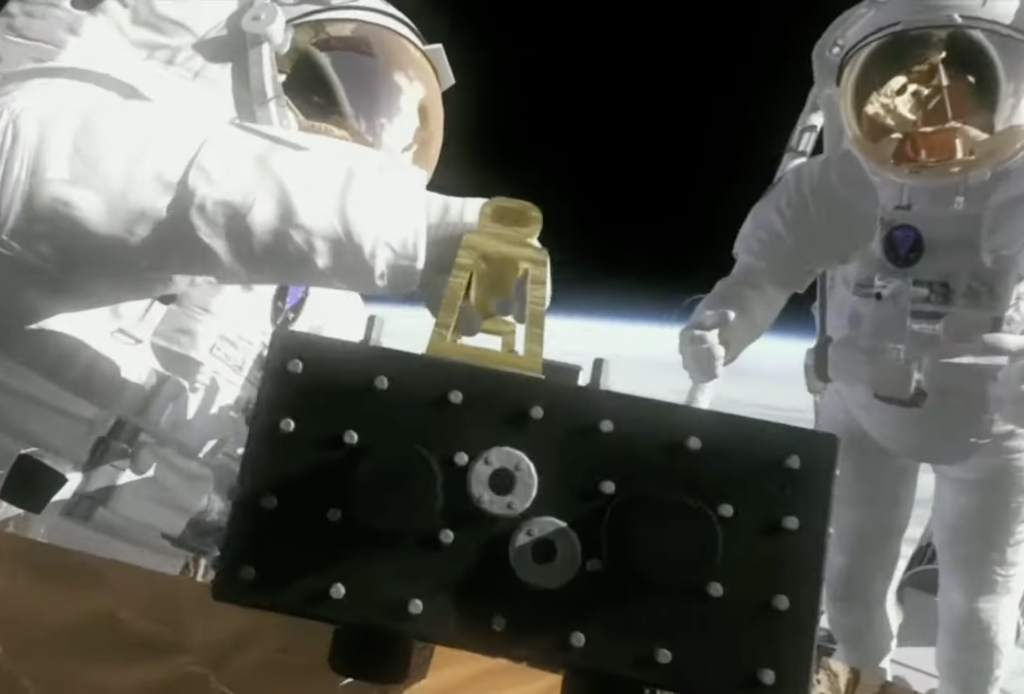

Featured picture exhibits a rendering of a mocked-up Metal3D system being utilized by astronauts. Picture through AddUp.

[ad_2]