[ad_1]

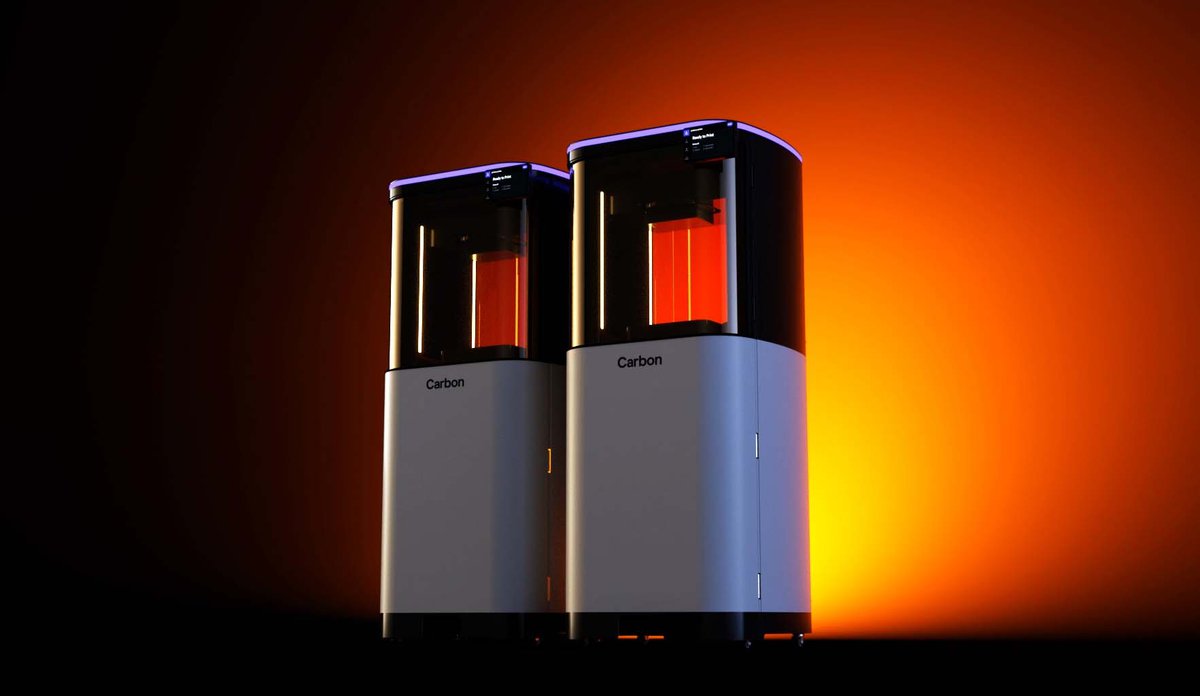

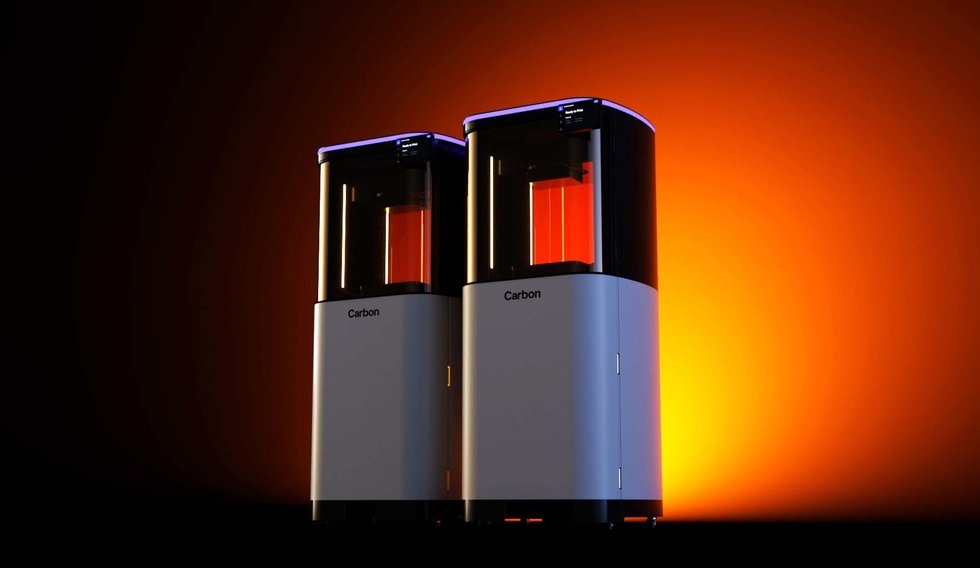

Carbon has introduced the launch of two M-Sequence 3D printing methods based mostly on its Digital Gentle Synthesis (DLS) expertise.

When mixed with Carbon’s Design Engine software program platform and vary of DLS supplies, the corporate says the M3 and M3 Max machines present a sophisticated end-to-end manufacturing platform.

The M3, which is obtainable for order instantly, is alleged to offer quicker and less complicated print expertise, whereas additionally boasting a extra constant floor end. Carbon’s M3 Max, in the meantime, provides the identical advantages however can be outfitted with a real 4K gentle engine, enabling double the construct space with the identical pixel measurement and density. It additionally includes a construct quantity twice the scale however provides the identical pixel measurement and density because the M3, serving to facilitate the printing of bigger functions. Each machines are stated to be appropriate for functions within the automotive, life sciences, dental, shopper merchandise and industrial sectors.

In bringing the brand new M3 methods to market, Carbon has endeavoured to make sure ‘considerably decrease’ forces on the half through the construct course of, whereas additionally offering closed-loop management of pressure and temperature to cut back failure modes. This helps to unlock extra geometries, particularly for elastomeric components. Higher warmth administration, in the meantime, ensures extra throughput per sq. foot in thermally restricted situations, with smoother components in comparison with prior generations additionally promised. Carbon additionally says the variation in components throughout a single construct has been lowered by as much as 50%.

“With these subsequent era printers — mixed with our Design Engine software program and Carbon DLS supplies — design groups throughout enterprise verticals can create high-quality prototypes with end-use efficiency faster and extra effectively than ever earlier than,” stated Phil DeSimone, Chief Product and Enterprise Improvement Officer at Carbon. “And as soon as the product growth is full, Carbon’s platform permits corporations to maneuver to manufacturing shortly and effectively wherever on the planet. We imagine this new era of Carbon DLS expertise will empower extra collaboration and assist to revolutionise how merchandise are designed and made.”

“Quick Radius makes use of Carbon’s printers and supplies to provide components for a variety of consumers, throughout various functions,” added Bobby Bott, VP of Manufacturing at Quick Radius, a Carbon Companion. “We’ve additionally leveraged the Carbon Design Engine—at the side of our personal software program capabilities—to assist prospects consider supplies and applied sciences to provide components that exceed high quality requirements and timelines. Having labored with Carbon for 5 years, we’re thrilled to proceed our partnership and produce the M3 capabilities to our prospects.”

Wish to focus on? Be part of the dialog on the Additive Manufacturing World Group Discord.

Get your FREE print subscription to TCT Journal.

[ad_2]