[ad_1]

Knaus Tabbert AG produces a variety of motor houses, caravans and panel vehicles, and their progressive designs and drive methods permits secure, snug and sustainable travelling. At its German headquarters in Jandelsbrunn, Bavaria, the corporate is consistently utilising its expertise to enhance the supplies and designs of its automobiles.

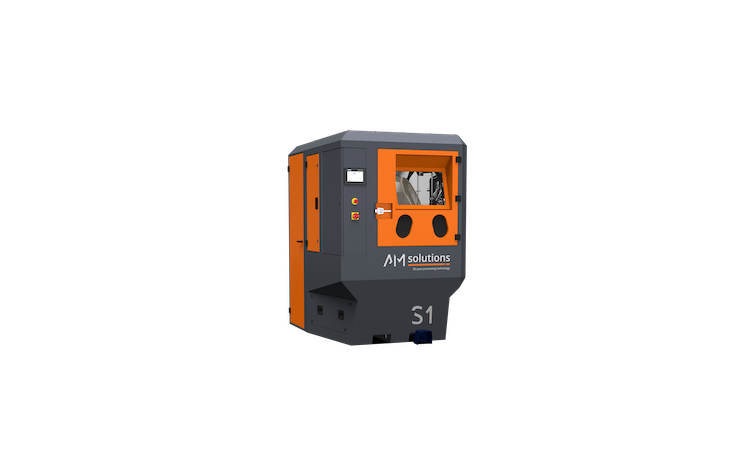

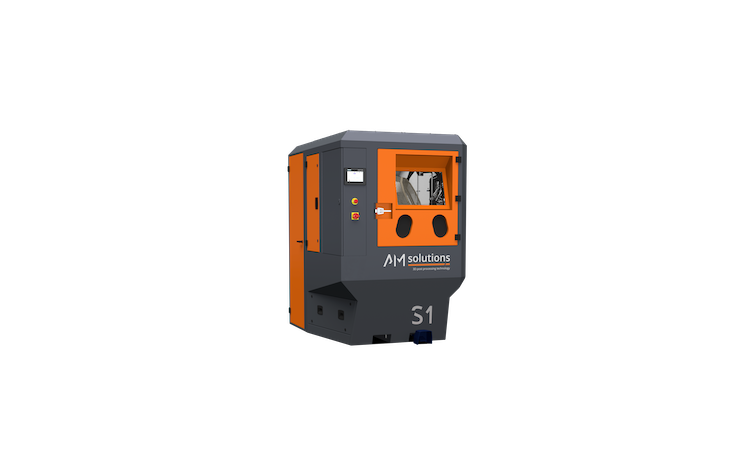

This consists of the seek for new applied sciences to make use of equivalent to additive manufacturing (AM) which led to the discovering of Resolution S1 by AM Options.

To date the de-powdering and cleansing of PA 12 Parts, produced by a powder-bed printing system has been completed manually in a blast cupboard, which requires a variety of labour and time, and the outcomes are extremely erratic and inconsistent.

Because of this, AM Options – a division of the Rosler Group that specialises in publish processing options for 3D printed merchandise – started operating complete processing trails with totally different elements at The Buyer Expertise centre for AM Options, which after conclusion of the profitable trials, the shopper selected the S1 shot blasting system.

The shot blast machine was particularly developed for the publish processing of plastic elements produced by the powder mattress printing technique and the plug and play S1 is the one machine available on the market that permits time-saving and cost-efficient de-powdering in addition to floor smoothing and homogenisation of 3D printed merchandise utilizing one machine, which may be completed by the straightforward change of blast media.

It’s outfitted with a basket which rotates in the course of the ending operation and permits simple loading and unloading of the work items and totally automated batch processing. All through the method the basket stays throughout the machine housing, which mixed with the door sealing system, prevents any powder spillages into the environment and the management panel may be simply switched to handbook with out retooling.

Manuel Laux, Head of AM Options – 3D Submit Processing Expertise stated: “An increasing number of firms from totally different industries are selecting the S1 for publish processing of their 3D printed elements and this can be a affirmation for our product technique, displaying that our 3D publish processing merchandise are in full compliance with the necessities of the market.”

Mario Meszaros, Improvement Engineer for Knaus Tabbert added: “The very fact after surprisingly brief cycle occasions the elements got here out of the machine completely clear and with none powder residues was very spectacular and with the underlying working knowledge I ready a ROI calculation, with the outcomes rapidly convincing our administration.

“Even with solely three print jobs per week within the S1, we already achieved a ROI after roughly two years, nevertheless it Is secure to imagine that the amount of 3D printed merchandise will improve considerably, which is able to dramatically scale back the amortisation course of.”

The usual model of the S1 additionally encompasses a system which mechanically displays and data all related course of parameters. The blast media has an built-in cleansing and recycling system and likewise an explosion protected design with the brief blast media with ATEX complainant motors and valves.

Mario added: “I’m completely satisfied that the straightforward, efficient and environment friendly publish processing potentialities of the S1 will additional promote using AM in our firm.”

Wish to talk about? Be a part of the dialog on the Additive Manufacturing International Neighborhood Discord.

Get your FREE print subscription to TCT Journal.

[ad_2]