[ad_1]

Insiders and analysts predict the 3D printing tendencies to look at in our newest collection of articles centered on the way forward for 3D printing.

Researchers from the Massachusetts Institute of Expertise (MIT) have developed a brand new methodology of 3D printing objects that change their look relying on the angle they’re seen at.

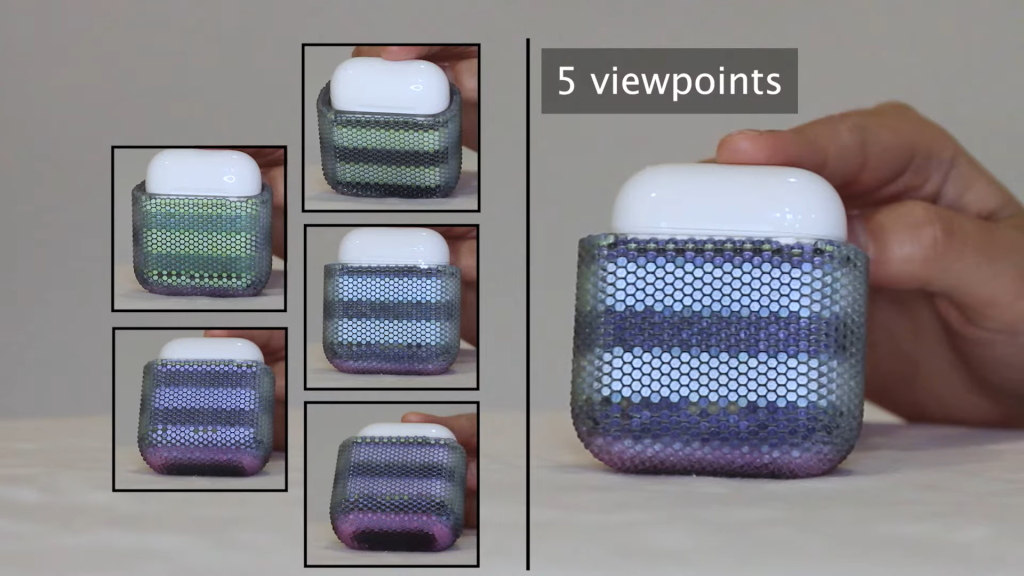

The strategy paves the best way for ‘programmable objects’ with morphing pictures, a visible characteristic that’s largely been restricted to flat 2D surfaces till now. The staff believes its work can drastically change the best way folks view product design, with on a regular basis 3D printed objects probably containing tons of of various colours and patterns relying on how they’re seen.

Naturally, the work may even have main implications for the humanities, enabling novel trend designs and sculptures that convey totally different aesthetics from totally different sides.

“Our work opens up the thought of what a bodily object could be,” says Yunyi Zhu, an MIT graduate scholar and co-first writer of the paper. “It’s half of a bigger imaginative and prescient for making dynamic objects that change their look, colour sample, and form. We handle look, which is one dimension of the idea of reprogrammable objects.”

3D printing lenticular objects

So how does it work? The novelty of the thought lies in its use of 3D printed lenticular lenses, that are tiny lenses that may enlarge the colours of the supplies they’re positioned on high of. Relying on the angle they’re seen at, lenticular lenses can diffract and mission totally different areas of the picture or sample they cowl. The MIT staff managed to suit six of those lenses throughout the floor of a dime.

By 3D printing the lenses (and the curved, patterned surfaces beneath the lenses), it’s doable to create a complete 3D lenticular show, which collectively exhibits a picture that varies based mostly on the perspective.

Based on Zhu, the largest problem within the mission was fine-tuning the dimensions of the printed lenses. Smaller lenses supply higher decision but additionally are inclined to have extra defects, resulting in decrease picture high quality. The staff ultimately settled on a lens diameter of 3mm, as this was the candy spot.

Numerous printing orientations and post-processing strategies have been additionally put to the take a look at in a bid to maximise colour transmission. The very best outcomes have been yielded by upwards-facing lenses that have been handled with portray varnish.

A free lenticular object design software

To enhance the 3D printing approach, the MIT researchers additionally developed a free enhancing software program permitting customers to design and construct their very own lenticular objects. To make use of the software, customers merely add a 3D mannequin and the specified patterns or pictures for the floor of the thing. The software program then mechanically calculates the lens placement and patterning that can obtain the specified outcomes. The half, pictures, and lenses can all be 3D printed in a single go.

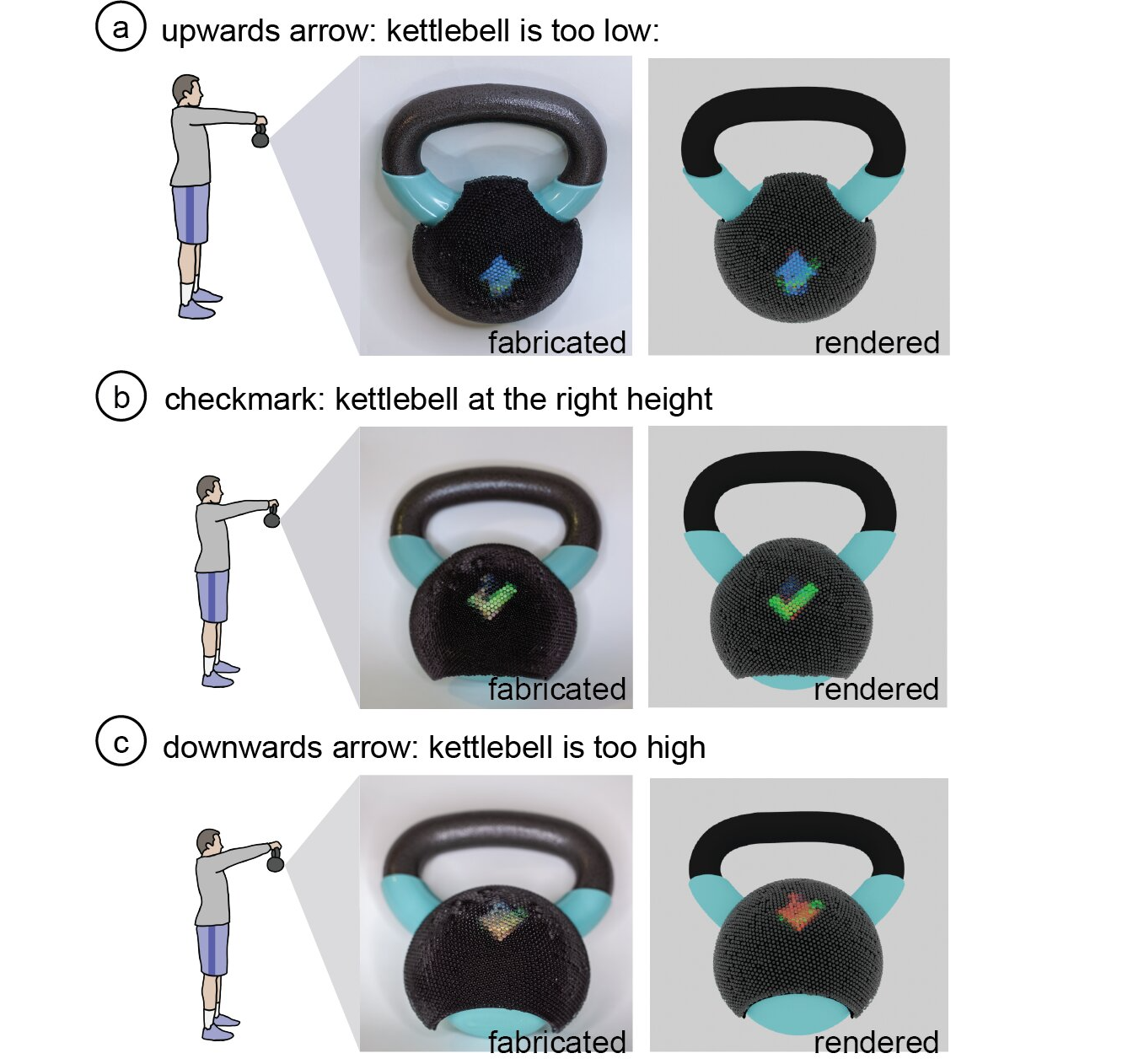

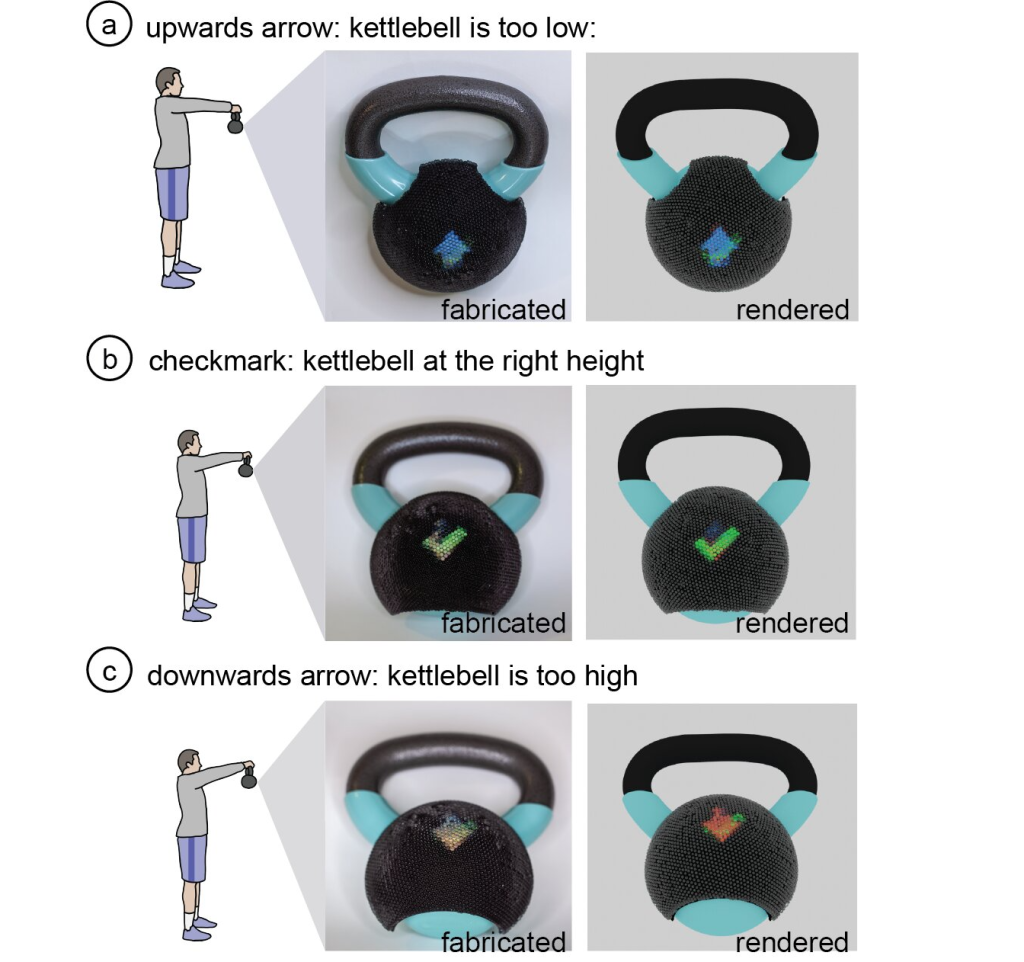

To show the lenticular 3D printing methodology, the staff has already printed quite a few prototypes. This contains an train kettlebell that exhibits the person whether or not or not they’re holding it appropriately, a bedside lampshade that shows ‘Good Day’ or ‘Good Evening’ relying on the viewing angle, an AirPod case that shimmers, and a shoe that exhibits a pleasant message solely to the wearer.

Additional particulars of the mission could be discovered within the paper titled ‘Lenticular Objects: 3D Printed Objects with Lenticular Lens Surfaces That Can Change their Look Relying on the Viewpoint’.

The extraordinary minds at MIT have been the supply of a number of 3D printing improvements through the years. Simply this month, researchers on the college developed a brand new methodology of invisibly embedding info into bodily objects utilizing 3D printing know-how. The idea is called ‘InfraredTags’ and it’s all about embedding IR-readable barcodes and QR codes throughout the interiors of 3D printed components. Seen solely to devoted IR sensors, these tags are designed to be invisible to the bare eye.

MIT researchers have additionally developed a methodology of 3D printing objects that may sense person interplay. The novelty is that the objects are 3D printed from a single piece of fabric (or metamaterial, extra exactly), with electrode sensors built-in into the fabric construction itself. As such, the printed constructions are capable of detect numerous adjustments in state, together with utilized forces and rotations.

Subscribe to the 3D Printing Business e-newsletter for the most recent information in additive manufacturing. You can even keep related by following us on Twitter, liking us on Fb, and tuning into the 3D Printing Business YouTube Channel.

On the lookout for a profession in additive manufacturing? Go to 3D Printing Jobs for a number of roles within the trade.

Featured picture exhibits a kettlebell with a 3D printed floor that tells the person how one can maintain it correctly. Picture by way of MIT.

[ad_2]