[ad_1]

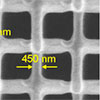

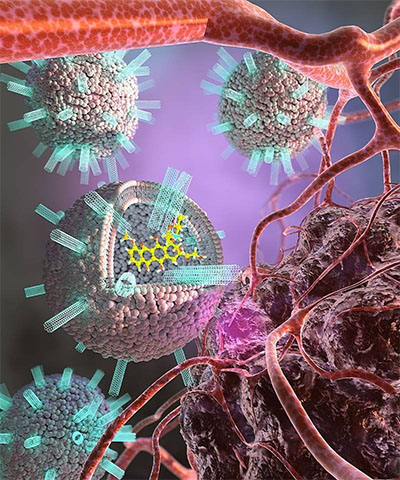

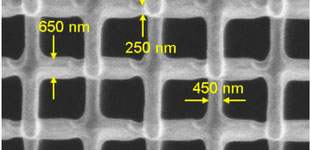

(Nanowerk Information) A newly created nano-architected materials reveals a property that beforehand was simply theoretically attainable: it may possibly refract mild backward, whatever the angle at which the sunshine strikes the fabric.

[ad_2]