[ad_1]

Researchers at Iowa State College have efficiently examined a novel method to 3D printing electronics in zero-gravity situations.

Instead of gravity, the group’s know-how successfully makes use of electrical pressure to print conductive inks onto a glass base layer-by-layer, in a manner that permits for the creation of complicated circuitry. Working with NASA, the engineers purpose to develop the method into a method of manufacturing sensors in house, that reduces astronauts’ reliance on carrying spares, and makes long-haul spaceflight extra possible.

“For future NASA missions, house exploration missions, they wish to not solely ship individuals there and again but additionally amenities for the long run,” explains Hantang Qin, the analysis group’s principal investigator. “That’s what we’re making an attempt to do. We’re constructing the printer, so the printer can keep on the Worldwide Area Station (ISS) or on Mars for a very long time.”

Repairing electronics on the fly

Onboard spacecraft, it’s not unusual for digital tools similar to sensors to interrupt, inflicting points with the potential to jeopardize their missions. Within the case of the humidity sensors onboard the ISS, for example, these are important to the security of its crew, and if the units malfunction, they should be changed or repaired as a matter of urgency.

Though transport replacements to the bottom could sound like the plain answer to this drawback, doing so makes the craft deployed throughout provide missions heavier, which in flip, makes the operation significantly dearer to hold out.

To get round this, a gaggle of researchers referred to as the No-Gravity Ink Jet Printing for Aeronautics and Area or ‘NINJAS’ group have give you an alternate. Developed at Qin’s Versatile Electronics and Additive Printing Lab, the engineers’ method includes utilizing an electrohydrodynamic inkjet printing mechanism to create components from novel patent-pending silver and barium titanate inks.

In accordance with the group, these supplies are well-suited to electronics manufacturing as they permit for ultra-stable, high-resolution printing, and with additional R&D, they may allow the creation of a brand new class of versatile sensors, mushy robotics, circuit boards, semiconductors and different micro-devices, each in house and right here on terra firma.

As a primary step in direction of placing their method to the check, Qin and his group constructed a prototype 3D printer in late-2021, whereas Iowa State colleague Shan Jiang labored from his lab to excellent his set of conductive inks forward of parabolic flight checks.

“The primary purpose of our experiment was to print a conductive circuit sample in microgravity,” added Qin. “We examined a number of varieties of ink with completely different materials properties, similar to density, floor pressure and permittivity, whereas pinpointing the optimum working situations, together with voltage, pulse frequency and nozzle orientation.”

The NINJAS zero-gravity experiment

As soon as their prototype was prepared for testing, the NINJAS crew took it to Fort Lauderdale in Florida, the place it was flown by a refitted airplane on which situations simulated these in outer house. The plane was in a position to obtain this by regularly flying up and down at 45º angles, permitting, on the very high of this curve, the group and their experiments to expertise brief durations of weightlessness in microgravity.

Nevertheless, whereas the engineers acknowledge that parabolic flight testing was the one manner of assessing their 3D printer’s efficiency with out going into house, they emphasize that managing to function the system in zero-gravity was no imply feat in itself, and described it as akin to “leaping from a constructing that’s 30,000 ft excessive for 20-30 seconds.”

“The zero-gravity setting wasn’t even that troublesome to regulate to the sensation of,” defined Matthew Marander, one of many Iowa State college students that flew as a part of the undertaking. “What I felt was harder to cope with was the sensation of speedy transition between hyper-gravity, the traditional gravity and zero-gravity. Switching between all of them so rapidly can really feel just a little bit disorienting.”

When it comes to the printer’s efficiency, Jiang concluded that the primary day of the three-day check was a studying expertise for all concerned, however over the second and third, the group had been in a position to 3D print “some good patterns.” Following their preliminary success, the researchers have now doubled down on their analysis, growing upgrades for his or her system and supplies forward of a second check in Might 2022.

Via their $420,000 undertaking, Jiang added that the group in the end “desires to assist NASA develop a platform that may drastically broaden the supplies and units they’ll make in house,” and so they’ve subsequently set themselves the longer-term purpose of developing with a novel nozzle head for the ISS printer earlier than 2024.

In-orbit 3D printing in-action

NASA continues to pour a major period of time, effort and money into finishing up Low Earth Orbit (LEO) 3D printing experiments, with essentially the most promising applied sciences occurring to be examined onboard the ISS. Simply final 12 months, a European Area Company consortium got here up with an early-stage FFF 3D printer, mentioned to be able to creating ‘limitless size’ components, which has been earmarked for the ISS.

Previously, the likes of Made in Area (now Redwire), have helped construct techniques for the ISS as nicely, and the agency performed a key function in growing the station’s plastic recycling facility for 3D printed components in 2019. Referred to as the ‘Braskem Recycler,’ the machine converts the ISS’ plastic waste into feedstock, enabling it to cut back its reliance on provide missions, and set up a near-closed loop manufacturing setup.

Away from the ISS, researchers on the Munich College of Utilized Sciences have additionally developed an in-orbit satellite tv for pc 3D printer, which could possibly be able to creating photo voltaic panels or antennas within the vacuum of house. Equally to Iowa State’s NINJAS program, the undertaking was initiated with the purpose of decreasing pointless weight onboard spacecraft, and permitting them to hold extra important cargo similar to gas.

To remain updated with the most recent 3D printing information, don’t neglect to subscribe to the 3D Printing Trade publication or observe us on Twitter or liking our web page on Fb.

For a deeper dive into additive manufacturing, now you can subscribe to our Youtube channel, that includes dialogue, debriefs, and pictures of 3D printing in-action.

Are you on the lookout for a job within the additive manufacturing trade? Go to 3D Printing Jobs for a choice of roles within the trade.

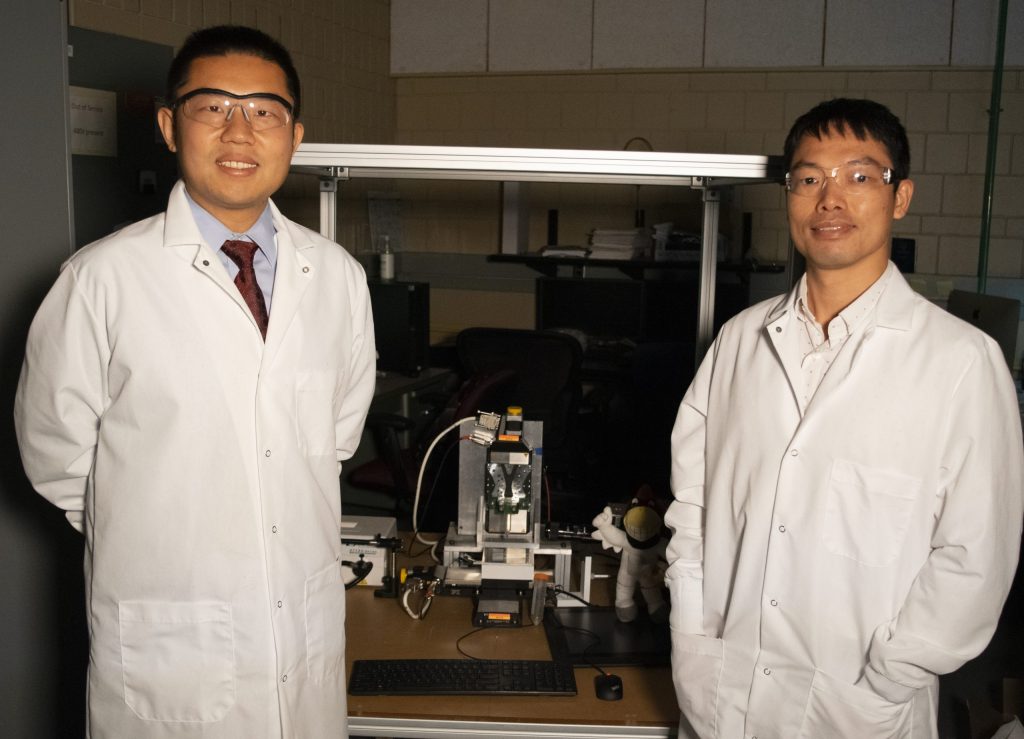

Featured picture exhibits the Iowa State College NINJAS researchers throughout their parabolic check flight. Picture by way of Steve Boxall/Zero-G.

[ad_2]