[ad_1]

Insiders and analysts have made their predictions on the 3D printing tendencies to be careful for. Discover out extra in our sequence targeted on the way forward for 3D printing.

Oak Ridge Nationwide Laboratory (ORNL) has patented a novel cable-driven building course of wherein a nozzle can be utilized to 3D print total buildings whereas suspended in mid-air.

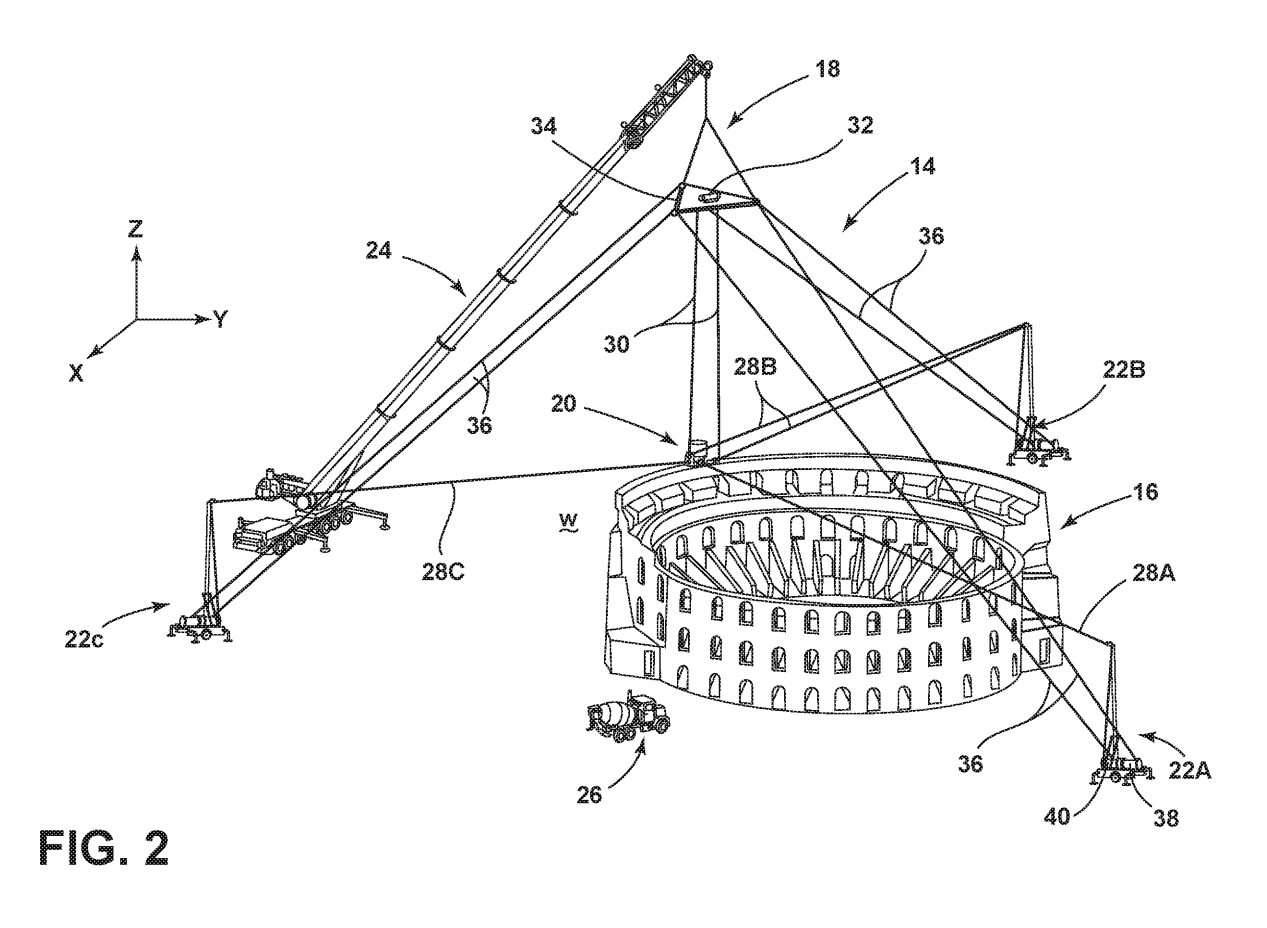

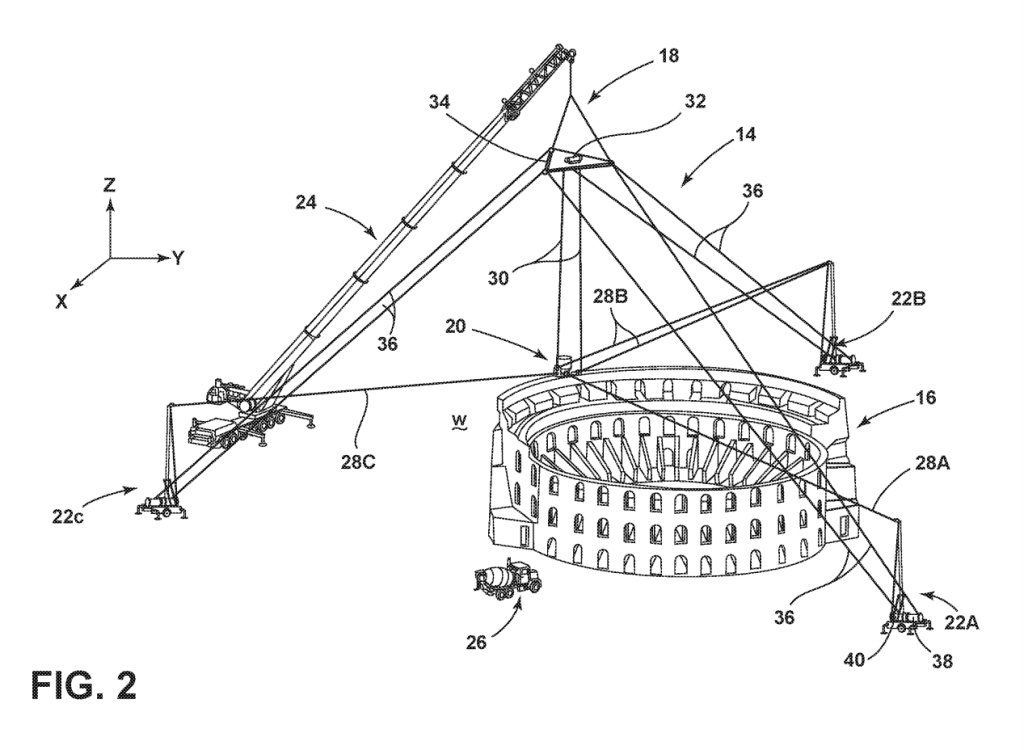

Nicknamed Sky Massive Space Additive Manufacturing, or ‘SkyBAAM’ for brief, the expertise is designed to be operated utilizing cords connected to cable winders, that present customers with full spatial management over the actions of its finish effector.

SkyBAAM’s creators say that its ease of setup eliminates the necessity for the intensive web site preparation at the moment required when deploying gantry-mounted techniques, which is “stopping them from turning into commercially viable.”

In accordance with the patent paperwork, which have been printed on FedInvent, it covers “cable-driven AM techniques that embody an finish effector configured for linear translation inside a three-dimensional workspace, an aerial hoist suspending the top effector by a minimum of one suspension cable, a plurality of base stations disposed beneath the aerial hoist and management cables operating from every.”

ORNL’s gantry 3D printing various

Within the preface of their patent, the crew behind SkyBAAM make the case that utilizing standard processes, establishing the typical household residence generates 3-7 tons of concrete waste. Against this, the ORNL engineers say that leveraging 3D printing to take action allows the creation of extra sustainable constructions with “distinctive geometries,” whereas utilizing “a lot much less materials” and power besides.

Many present building techniques characteristic nozzles mounted to a gantry framework, in a method that permits customers to scale their concrete deposition as wanted, and construct constructions as much as three storeys in peak. Utilizing COBOD’s gantry BOD2 printer, as an illustration, the PERI Group has beforehand been in a position to erect a three-floor residence constructing in Germany, and gone on to record it on the nation’s rental market.

ICON has additionally attracted a big quantity of investor curiosity in its Vulcan expertise, and the agency has now raised over $266 million in funding to help its ongoing improvement. Whereas not connected to gantry in the identical method as different building 3D printers, even the next-gen Vulcan, which was unveiled mid-2021, encompasses a printhead that’s mounted onto and moved by parallel base stations.

But, regardless of rising curiosity in such 3D printers, the ORNL crew has criticized their complicated setups, which they are saying are a “barrier to their industrial implementation.” The engineers additionally recommend that present printed constructions aren’t as “aesthetically pleasing” as these made out of different facade supplies, they usually can require prolonged reinforcing, thus an “improved large-scale, fieldable” system is required.

Cable-driven SkyBAAM building

Versus standard concrete 3D printers, the SkyBAAM system outlined in ORNL’s patent is designed to be operated utilizing a sequence of pulleys, which may be managed by way of on-site base stations. On the tip of the machine, is a suspended finish effector, on which its stated that any cement-compatible nozzle may be connected, in addition to a growth, able to carrying a hose for supplying this with materials.

In follow, the SkyBAAM’s inventors say that two of its base stations ought to be fitted with actuators resembling cable winders, with a purpose to transfer its nozzle into place, with a 3rd getting used as a passive base, offering solely pressure management. Nonetheless, the researchers have additionally left some wiggle room for the system to be custom-made, with extra stations, cable guides or an auto-operated central controller.

In accordance with the machine’s patent, one of many most important advantages to switching from a gantry to a cable-mounted setup, is that pulleys may be releasably secured, making the latter a lot simpler to deploy. What’s extra, the system’s design is alleged to allow it to function with simply three levels of freedom, in comparison with the six required by regular cable-driven techniques, making it each easier and extra fieldable.

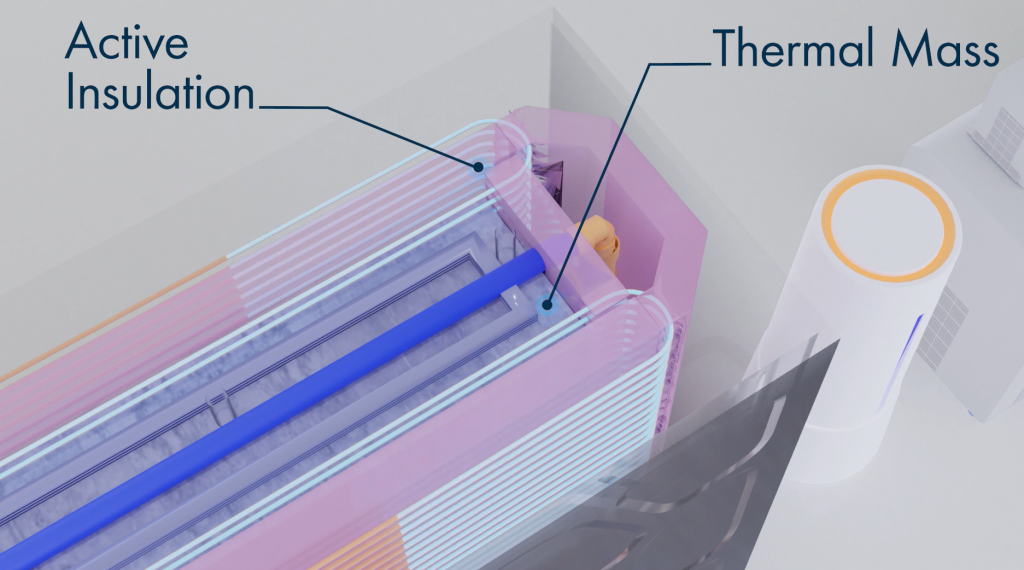

The SkyBAAM 3D printer should still be at an early stage of improvement, however this hasn’t stopped the ORNL from deploying it on an experimental degree, and in Might 2020, its researchers used the expertise to construct a first-of-its-kind ‘Sensible Wall,’ that includes built-in electronics, that enabled it to function an energy-efficient room cooling system.

“What makes SkyBAAM distinctive is that it eliminates the necessity for a gantry system generally present in large-scale additive manufacturing techniques,” ORNL researcher Brian Submit stated on the ‘EMPOWER’ Sensible Wall’s unveiling again in 2020. “It may be arrange inside hours at a building web site with minimal web site preparation.”

Readers can discover a full breakdown of ORNL’s SkyBAAM 3D printing expertise beneath patent quantity ‘11230032’ right here.

Ongoing additive innovation at ORNL

ORNL continues to behave as a hub for 3D printing innovation, with the group’s researchers having achieved a number of advances that assist the expertise’s wider utility, within the final yr alone. Earlier this month, the Extremely Protected Nuclear Company licensed an ORNL-developed nuclear half 3D printing methodology, in a transfer that would assist make it a commercially viable manufacturing course of in future.

Late final yr, the group additionally introduced it had give you a novel water-soluble plastic binder that may be 3D printed into elements with “distinctive power.” Utilizing the fabric, which is alleged to have twice the power of standard binders, ORNL researchers have been in a position to construct a silica sand bridge able to holding 300 occasions its personal weight.

On this planet of building, in the meantime, ORNL engineers have beforehand labored with these at Cincinnati Integrated, to develop a recycled materials 3D printing setup for its Massive Space Additive Manufacturing (BAAM) system. By the creation of an revolutionary extruder design with a twin materials feed, the crew had been finally in a position to robotically 3D print a ten-foot multi-material composite device.

To remain updated with the most recent 3D printing information, don’t overlook to subscribe to the 3D Printing Business publication or comply with us on Twitter or liking our web page on Fb.

For a deeper dive into additive manufacturing, now you can subscribe to our Youtube channel, that includes dialogue, debriefs, and photographs of 3D printing in-action.

Are you on the lookout for a job within the additive manufacturing trade? Go to 3D Printing Jobs for a number of roles within the trade.

Featured picture exhibits a schematic of the ORNL ‘SkyBAAM’ 3D printing system. Picture by way of FedInvent.

[ad_2]