[ad_1]

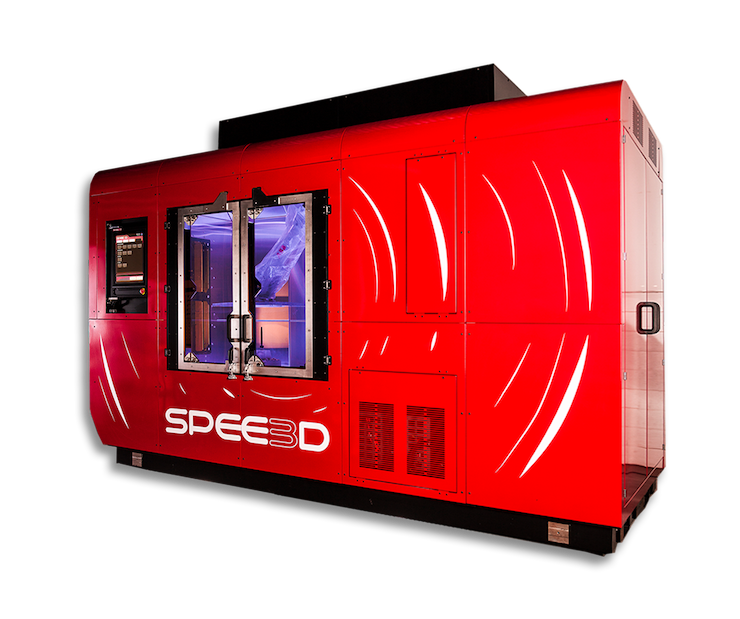

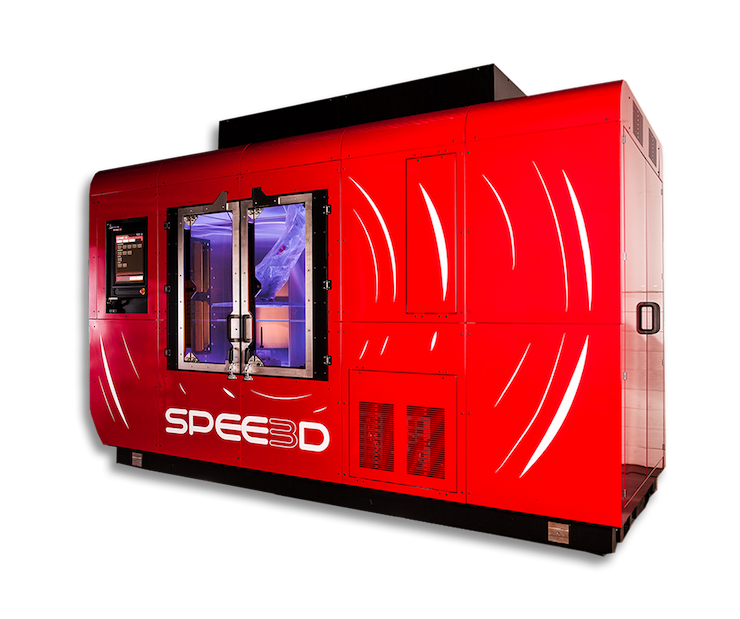

Phillips Federal introduced they’ve signed an settlement with SPEE3D – an Australian firm which provides metal-based additive manufacturing (AM) know-how – to amass a brand new WarpSPEE3D Steel AM printer.

The WarpSPEE3D CSAM know-how will likely be assigned to their Centre of Innovation, which is co-located on the Rock Island Arsenal’s AM Centre of Excellence. It is going to be utilized by Phillips Federal and the US Military to additional develop the centre’s additive manufacturing capabilities and to create massive format, parts-on-demand steel purposes for the US Military.

Phillips Federal will likely be add the machine to the centre this yr to additionally help actions in materials exploration and analysis, in addition to the event and manufacturing of future large-format purposes and prototypes for the Military et el Armed Forces.

Phillips Company, Federal division, a number one service supplier and manufacturing companion to the US Federal Authorities, first added steel AM applied sciences from SPEE3D in 2020 to help its Public Personal Partnership (P3) and Additive Manufacturing programmes on the US Military’s Rock Island Arsenal (RIA).

John Harrison, World Director of Phillips Additive stated: “Since 2020, the distinctive high-speed capabilities of SPEE3D know-how have confirmed to be a wonderful addition in supporting the RIA’s manufacturing innovation goals, and the scope of our P3 programme and the brand new WarpSPEE3D printer on the RIA’s Centre of Excellence for Superior Manufacturing facility will permit us to additional our scope and make cutting-edge achievements in creating large-format purposes for expeditionary forces within the US.”

The WarpSPEE3D printer has been regularly utilized by Defence Forces for over two years for an on-demand, deployable steel manufacturing functionality, and between 2020-2021, the Australian Military performed a number of subject trials with their WarpSPEE3D tactical printer.

In 2020, the exams resulted in over 50 case research of printable elements, demonstrating the printers’ strong capabilities for use in Australian bushland and in 2021 – when the programme was prolonged to confirm preliminary outcomes, together with the institution of latest subject trails and the Australian Military AM Cell technicians – it was efficiently proved attainable to 3D print, certify, validate and change armoured autos within the subject, exhibiting that AM may play an element in the way forward for defence readiness.

Bruce Colter, SPEE3D’s Vice President and Normal Supervisor of North America stated: “ We anticipate the supply of this new WarpSPEE3D printer to offer Phillips Federal and The Rock Island Arsenal with extra capabilities from our patented Chilly Spray AM know-how, the quickest steel 3D printing functionality on this planet, and WarpSPEE3D printers have demonstrated in subject trails that they will make high-quality steel elements on-demand that are crucial to maintain army gear and autos operational, and the American AM house is rising quickly, and SPEE3D’s know-how is simply rising quickly with it.”

Byron Kennedy, CEO of SPEE3D added: “We consider this growth is an thrilling alternative for SPEE3D and DoD forces. Our smaller LightSPEE3D system has been used as a part of the RIA programme with nice success and with a WarpSPEE3D, Phillips Federal and The Rock Arsenal will be capable of discover a variety of huge, high-quality, low-cost steel elements manufactured rapidly.”

Wish to talk about? Be a part of the dialog on the Additive Manufacturing World Group Discord.

Get your FREE print subscription to TCT Journal.

[ad_2]