[ad_1]

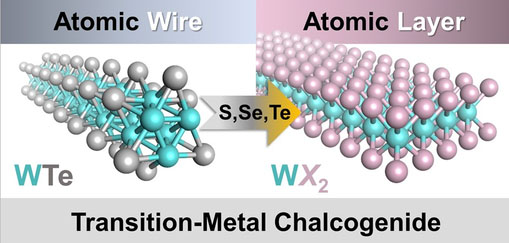

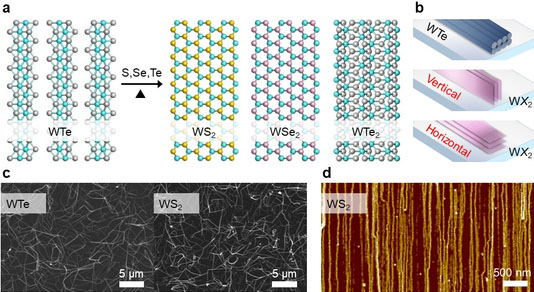

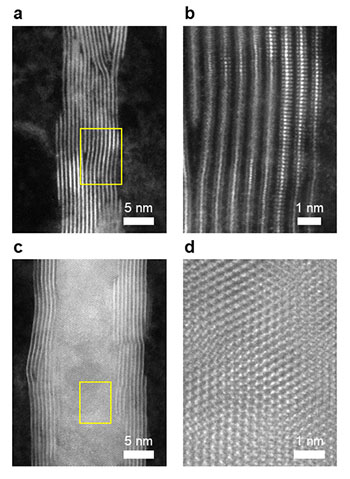

(Nanowerk Information) Researchers from Tokyo Metropolitan College have succeeded in utilizing nanowires of a transition-metal chalcogenide to make atomically skinny nanoribbons. Bundles of nanowires had been uncovered to a gasoline of chalcogen atoms and warmth which helped merge the threads into slender strips (ACS Utilized Nano Supplies, “Nanowire-to-Nanoribbon Conversion in Transition-Steel Chalcogenides: Implications for One-Dimensional Electronics and Optoelectronics”).

[ad_2]