[ad_1]

Insiders and analysts have made their predictions on the 3D printing traits to be careful for. Discover out extra in our sequence centered on the way forward for 3D printing.

High quality assurance software program developer Sigma Labs has partnered with 3D printing service supplier Materialise to develop a know-how that permits for the real-time correction of errors throughout metallic additive manufacturing.

Successfully a mixture of Sigma Labs’ PrintRite3D system and Materialise’s Management Platform, the setup is exclusive in that it permits customers to determine and deal with points that come up as alloy powders are fused collectively. Hailing the brand new platform as a “breakthrough” in metallic 3D printing, Materialise says that it might now permit adopters to reinforce the consistency and scalability of their workflows.

“The platform is open and versatile permitting producers to take management of their particular processes to suit their distinctive purposes,” explains Materialise CTO Bart van der Schueren. “This makes it doable for purchasers to leverage their experience and really reap the benefits of the customization and localization advantages that AM offers.”

“The platform we’ve developed eliminates one of the crucial widespread roadblocks for producers thinking about utilizing metallic additive manufacturing for serial manufacturing.”

Sigma Labs’ QA experience

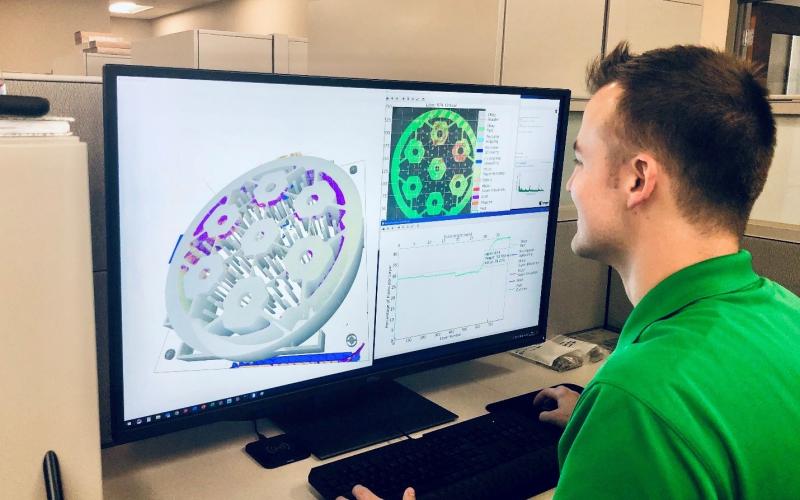

Whereas Materialise has its fingers in lots of pies, with software program, manufacturing and consultancy choices, Sigma Labs focuses solely on high quality assurance in manufacturing. Via its important product, PrintRite3D, the agency markets an answer made up of software program and {hardware} monitoring modules, that use real-time information to uncover half defects, earlier than deploying machine studying to map their root causes.

Designed to be platform agnostic, the system can both be put in as a retrofit to an present machine, or requested as a manufacturing unit choice from printer producers. Nonetheless, regardless of the broad compatibility and half defect evaluation advantages of its important product providing, Sigma Labs’ income stays low, thus it continues to hunt out new adopters and methods of addressing the broader 3D printing market.

In March final yr, as an example, the corporate was awarded a contract by Lockheed Martin, which noticed the viability of its applied sciences assessed for varied protection and civil house applications, whereas on the R&D entrance, it has since made PrintRite3D polymer-compatible, in a transfer that has successfully expanded the system’s purposes.

Now, after the disclosing of Sigma Labs and Materialise’s new platform, the agency’s CEO Mark Ruport says that the companies can proceed working collectively in future, to broaden each the scalability and attraction of metallic 3D printing.

“We consider the mix of the Materialise Management Platform with Sigma’s real-time soften pool monitoring and analytics software program, has created a big breakthrough within the AM trade,” provides Ruport. “I look ahead to future alternatives to collaborate and discover methods to proceed to enhance the standard and consistency of 3D metallic printing, as extra firms go into manufacturing within the coming years.”

A metallic 3D printing “breakthrough”

In an effort to create their new monitoring system, Sigma Labs and Materialise have basically merged their respective PrintRite3D software program and Management Platform {hardware} applied sciences collectively. The primary part of the latter is principally an add-on, which might be embedded by customers into laser-based machines, as a method of gaining enhanced print parameter management.

In its standard guise, the know-how permits adopters to entry over 250 settings to determine the best manufacturing setup, whereas its structure is constructed to work with as much as 16-laser multi-optic techniques. Mentioned to be appropriate with all PBF and SLM techniques, Materialise’s platform additionally contains an computerized calibration instrument API, that’s designed to allow customers to simply maximize their manufacturing effectivity.

By combining this platform with Sigma Labs’ PrintRite3D know-how, the businesses have developed a method of pinpointing potential high quality points, and intervening to appropriate them earlier than prints are spoiled past restoration. In doing so, Materialise says that the companies have give you a manner of enhancing metallic 3D printing’s productiveness and effectivity, that permits adopters to scale into serial manufacturing.

What’s extra, the corporate believes that the brand new platform additionally has the potential to handle the “want for post-build inspection and high quality assurance” that may make metallic 3D printing dearer than many conventional applied sciences, particularly on condition that it could both be put in on new machines or fitted to enhance the print high quality of present techniques.

Actual-time metallic printing monitoring

Though quite a few real-time metallic 3D printing monitoring options have been developed over the previous few years, these have largely remained experimental, and never been utilized inside industrial settings. Late final yr, a workforce at Lawrence Livermore Nationwide Laboratory got here up with a novel high-speed videography-based strategy to optimizing the metallic materials jetting course of.

In terms of monitoring powder-based techniques, researchers at Oak Ridge Nationwide Laboratory have additionally developed an AI-based real-time monitoring software program. Referred to as ‘Peregrine,’ the algorithm is designed to evaluate the standard of elements throughout manufacturing, and function a probably cost-effective different to dear lab characterization gear.

Up to now, comparable applied sciences have additionally attracted army backing, with metallic 3D printing initiatives on the College of Texas at El Paso gaining US Military Analysis Lab funding, and extra lately, Senvol’s machine studying software program being awarded contemporary funding by the US Division of Protection, to increase on its ‘ML’ platform’s additive manufacturing materials and course of qualification capabilities.

To remain updated with the most recent 3D printing information, don’t overlook to subscribe to the 3D Printing Business e-newsletter or observe us on Twitter or liking our web page on Fb.

For a deeper dive into additive manufacturing, now you can subscribe to our Youtube channel, that includes dialogue, debriefs, and pictures of 3D printing in-action.

Are you in search of a job within the additive manufacturing trade? Go to 3D Printing Jobs for a number of roles within the trade.

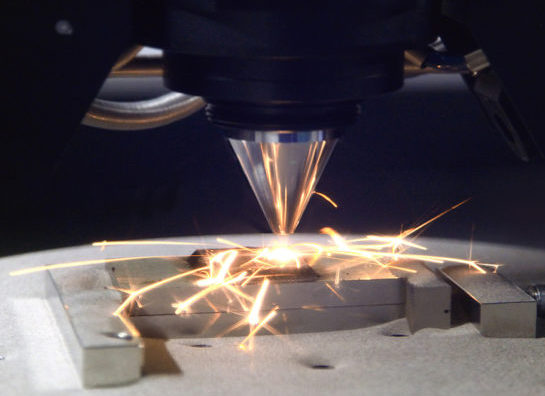

Featured picture reveals an element being 3D printed whereas being monitored utilizing Sigma’s PrintRite3D software program. Photograph through Sigma Labs.

[ad_2]