[ad_1]

SuperStile – a specialist design and manufacturing companion for automotive manufacturers – has bought a big format Stratasys F770 3D Printer to extend the capability of its already current industrial grade FDM primarily based additive manufacturing (AM) functionality, offering higher agility in assembly buyer necessities for correct and larger-sized elements.

The corporate specialises within the design and growth of exterior and inside bodywork for idea fashions, working prototypes and show-cars, and has produced work for quite a lot of massive chains together with Ferrrari, Giugiaro, Stellantis and BMW.

It already makes use of a Stratasys Fortus 380 3D printer, however in keeping with co-founder and Basic Supervisor Franco Palmisano, SuperStile will leverage the F770’s spacious construct capability to tackle an expanded vary of tasks, while sustaining its potential to satisfy deadlines.

Franco Palmisano mentioned: “We’ve chosen the F770 for 3 key causes and with its mega-build quantity, it is going to ramp up the vary of prototyping jobs that we’re capable of tackle for patrons. It additionally provides us higher manufacturing bandwidth throughout our 3D printing necessities – however importantly through an industrial-grade additive manufacturing know-how that has efficiently confirmed itself to us through our Fortus 380.”

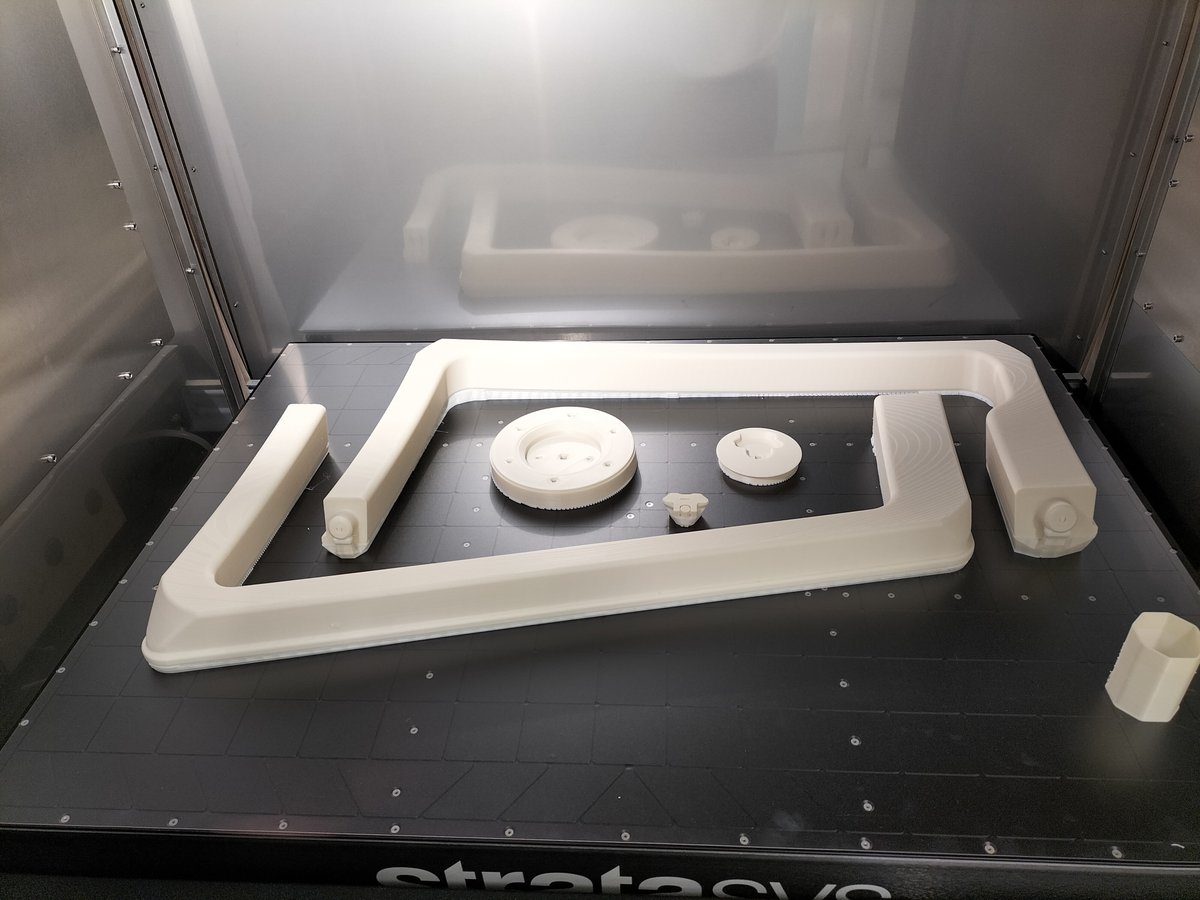

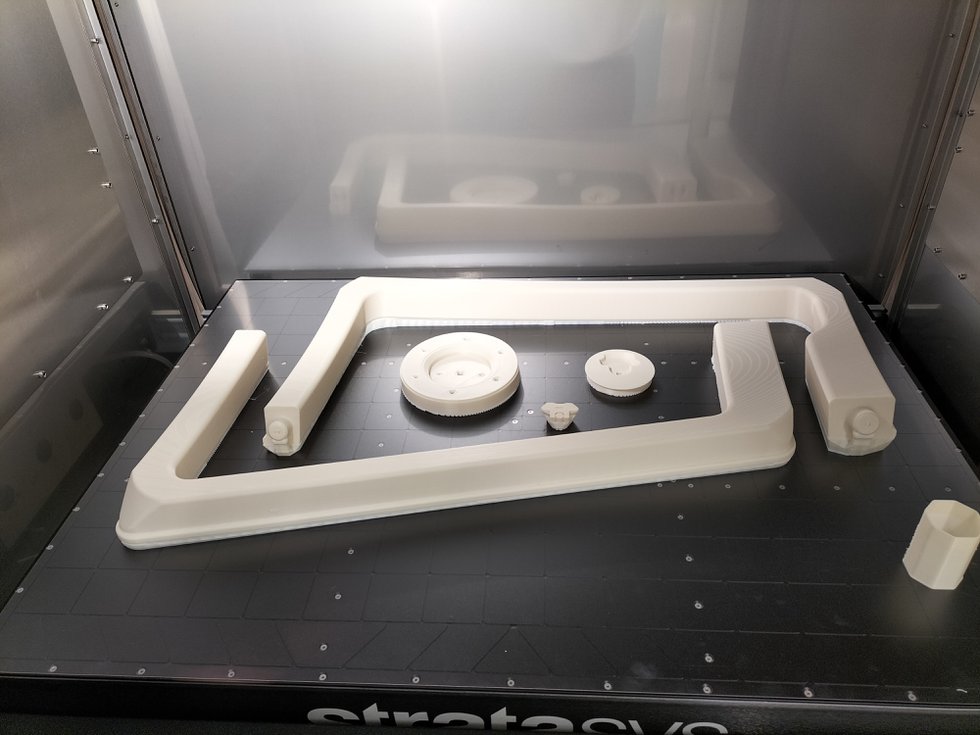

The brand new printer was put in by Stratasys Italian distributor, Overmach, who labored carefully with SuperStile to evaluate its wants and establish probably the most appropriate resolution and the F770 is now totally operational inside the firm’s prototyping division and has already been used to create varied fashions together with rear-view mirrors, door handles and air vents.

It’s the latest addition to Stratasys’ FDM-based 3D printers and is provided with a big totally heated construct chamber measuring 1000 x 610 x 610 mm, has the flexibility to print ABS-M30 and ASA thermoplastics and in addition makes use of soluble help materials, which permits correct and dependable prototype elements with complicated inner constructions to be designed and printed with minimal post-processing.

Regardless of additionally working conventional CNC gear which continues to play a job inside the enterprise, the flexibility of the Stratasys’ FDM-based 3D printing know-how has been seen to streamline design and growth actions for SuperStile.

Palmisano added: “Due to our now expanded 3D printing firepower, we’re effectively outfitted to proceed to push inventive boundaries and meet the ever-demanding necessities of our automotive clients.”

Need to talk about? Be a part of the dialog on the Additive Manufacturing World Neighborhood Discord.

Get your FREE print subscription to TCT Journal.

[ad_2]