[ad_1]

Information briefs for the week check out the Snowbot S1 robotic snowblower, Exotec’s mixed Skypod AS/RS and Skypicker choose n’ pack programs, Effibot’s “observe me” AMR, an exosuit’s impression on mobility for stroke victims, the largest-ever 3D-printed workplace constructing, and a “robust man” cellular robotic arm that unloads trailers at 800 packing containers per hour.

Chilly-weather robotic as autonomous snowblower

Snow elimination with highly effective, gas-powered house snowblowers is perhaps a troublesome act to observe for an autonomous, all-electric mannequin that may deal with solely a most of 12 inches (30 centimeters) of snow depth.

Shenzhen-based Hanyang Applied sciences, in advertising and marketing its “residential use” SnowBot S1 has a practical outlook in regards to the difficulties concerned with the various sorts of snow in addition to eradicating it, saying on its web site: “We all know there’s a lengthy method to go, for a better, simpler, and higher snow cleansing resolution.” The corporate is providing a $200 low cost for early-bird consumers (out there in October of 2022). Asking value: $1999. By comparability, the most affordable Husqvarna gas-powered machine, the ST124, retails for $699.

Shenzhen-based Hanyang Applied sciences, in advertising and marketing its “residential use” SnowBot S1 has a practical outlook in regards to the difficulties concerned with the various sorts of snow in addition to eradicating it, saying on its web site: “We all know there’s a lengthy method to go, for a better, simpler, and higher snow cleansing resolution.” The corporate is providing a $200 low cost for early-bird consumers (out there in October of 2022). Asking value: $1999. By comparability, the most affordable Husqvarna gas-powered machine, the ST124, retails for $699.

That mentioned, the SnowBot S1 is a sleek-looking, treaded snow warrior with a tough rubber-tipped auger that scrapes the snow off the bottom and into its housing earlier than expelling it from its chute for as much as 12 ft (about 3.6 meters) away. The Snowbot S1 is powered 4 high-efficiency motors working on a 1123 watt-hour, lithium-ion battery. “A full cost can work for 1.5 hours and clear an space of about 1500 sq. ft (for snow depth of 5 inches).”

LiDAR navigation and superior positioning algorithm assist Snowbot S1 to plot and autonomously execute a cleansing path. And it routinely stops when clogged.

Exotec’s Skypod system nabs $335M for enlargement

All through 2021, and fairly probably for the foreseeable future, spikes in e-commerce, continued COVID threats, and difficulties in recruiting staff have created an ideal storm for logistics distributors. Lille-based (France), Exotec, (based in 2015), simply nabbed $335 million (present valuation $2 billion) to scale its Skypod AS/RS and Skypicker choose n’ pack programs into the attention of the storm.

Exotec claims that its Skypod structure is certified at growing storage density over rival AS/RS programs. Skypods are low-profile, goods-to-person autonomous robots that may go up a rack system (as excessive as 36 ft) to select up a bin and ship it to a packing station. Now, with the addition of its latest SkyPicker system, the bins or totes could be unloaded and packed for cargo. Ever fewer staff are wanted to select, pack and ship e-commerce.

Exotec claims that its Skypod structure is certified at growing storage density over rival AS/RS programs. Skypods are low-profile, goods-to-person autonomous robots that may go up a rack system (as excessive as 36 ft) to select up a bin and ship it to a packing station. Now, with the addition of its latest SkyPicker system, the bins or totes could be unloaded and packed for cargo. Ever fewer staff are wanted to select, pack and ship e-commerce.

“After they climb within the rack, they go at nearly 5 ft per second, so this can be a very quick piece of apparatus,” says Gilles Baulard, the corporate’s EVP of gross sales.

“Exotec has at all times positioned its product as a service that may’t exchange people altogether. An Exotec warehouse is run by a mix of people and robots.” Nonetheless, with the addition of the Skypickers, Exotec is now positioning itself as a logistics benefit in a good labor market.

We didn’t invent the robotic, says Exotec CEO Romain Moulin, we simply invented the way to make them run in 3D, which, he claims, makes all of the distinction (see video).

Spanish automaker to make use of French Effibot (AMR)

Additionally becoming a member of within the rush to provide e-commerce and factory-helper AMRs (Autonomous Cellular Robots) is one other French logistics developer, Romagnat-based Effidence.

In collaboration with Spanish automaker SEAT S.A., Effidence developed its EffiBOT (AMR) and tailored the robotic’s operation to the processes at SEAT’s Martorell plant.

SEAT built-in Effibots that may ship elements to the meeting line and switch materials between totally different areas, which, says SEAT,  leads to elevated productiveness.

leads to elevated productiveness.

Usually, Effibot is an autonomous cart that operates like a dealing with assistant and can be utilized, claims the corporate, “in numerous use-cases, from selecting/kitting actions to elements supply, and in numerous warehouse and industrial environments.”

The Effibot can self-map a path to a given vacation spot and keep away from obstacles alongside the way in which. Additionally, it’s “follow-me” performance permits it to observe a employee, and “could be configured for an individual strolling in entrance, on the left aspect, or on the fitting aspect of the car.”

The navigation system offers it a driving pace of as much as 4 mph. Though a comparatively sluggish AMR, Effibot’s design affords secure aisle-crossing capabilities, can function on uneven surfaces with as much as 30-degree inclines, and can be capable of transfer two-ways as a way to enhance maneuverability.

Robots increase mobility outcomes for stroke victims

“Stroke sufferers are sometimes instructed they’ve one yr to recondition their our bodies after a stroke, after which that shall be pretty much as good because it will get.” One yr to rehab, and that’s it, is like giving somebody’s mobility a loss of life sentence.

For 72-year-old, stroke sufferer William Roquemore, it had been seven years, and he was deemed too far gone to profit from any rehabilitation.

Then, his life modified dramatically for the higher when he met up with the workers from the College of Texas’ TIRR Memorial Hermann Well being Middle and their Ekso GT Robotic Exoskeleton from Ekso Bionics.

Then, his life modified dramatically for the higher when he met up with the workers from the College of Texas’ TIRR Memorial Hermann Well being Middle and their Ekso GT Robotic Exoskeleton from Ekso Bionics.

TIRR Memorial Hermann workers director, Dr. Fangshi Zhu, needed to search out out if robot-assisted remedy may assist.

“The physician instructed my spouse I would be not more than a vegetable, however I received higher!” mentioned Roquemore enthusiastically, whereas strolling within the powered exosuit.

“Conventional remedy,” mentioned Zhu, “typically includes a couple of bodily therapist to manually convey your impaired limb to the specified location or trajectories, and it may be very labor intensive, and even unsafe some instances for the affected person and for the therapist.”

The exosuit by no means drained, and months of repetition paid off for Roquemore. He’s now the topic of successful paper within the Journal of Neural Engineering, and suggestions from his remedy classes helps Ekso Bionics make particular enhancements to the Ekso GT, which is able to assist different stroke sufferers to stroll once more.

3D tech prints largest-ever workplace constructing

Apis Cor, Florida-based robotic/3D printing development firm, used its expertise to construct the world’s largest 3D-printed constructing, a two-story workplace in Dubai, incomes the corporate a Guinness E-book World Report for the World’s Largest 3D Printed Constructing on Earth.

Though the 3D printer weighs 2 tons, it may be transported to varied websites due to its compact dimensions and requires about half-hour for set up. “The printer is nearly totally automated, although it requires two folks to function it and provide the fabric.”

Though the 3D printer weighs 2 tons, it may be transported to varied websites due to its compact dimensions and requires about half-hour for set up. “The printer is nearly totally automated, although it requires two folks to function it and provide the fabric.”

Sponsored by the Dubai Future Basis, the two-story constructing measures 20 ft by 120 ft lengthy by 40 ft extensive, and took 17 days to print; the inside took 3 months to design and construct out. In response to Apis Cor, the constructing “required 50 p.c much less manpower to finish when in comparison with conventional strategies of constructing.” The startup additionally met the problem of 3D printing in Dubai’s harsh setting with out humidity and temperature controls.

Apis Cor developed a gypsum-based, weatherproof materials to run by the printer; whereas the 3D-printing machine was moved by way of a crane to re-position to work the constructing course of. “The constructing sits on typical foundations, and the 3D-printed formwork for the columns was strengthened with concrete and rebar.”

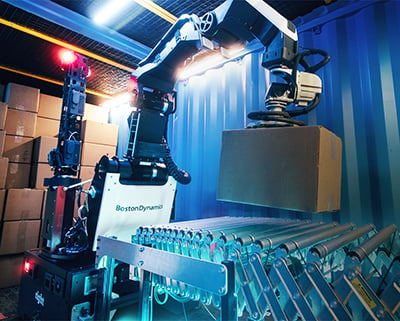

Stretch: warehousing’s new-best buddy

The worst job in a warehouse has a best-new buddy: Boston Dynamics’ Stretch robotic.

Frigid in winter, stifling in summer season, and at all times awkwardly backbreaking, unloading containers and trailers at warehouse loading/receiving docks is regarded by staff because the nastiest of duties.

“With its single huge arm, a gripper filled with sensors and an array of suction cups, and an omnidirectional cellular base, Stretch  can switch packing containers that weigh as a lot as 50 lbs. (23 kg) from the again of a truck to a conveyor belt at 800 packing containers per hour.”

can switch packing containers that weigh as a lot as 50 lbs. (23 kg) from the again of a truck to a conveyor belt at 800 packing containers per hour.”

The robotic weighs 2,650 lbs. (1,200 kg). With a base the identical dimension as a normal pallet of 48×40-inch, Stretch conveniently suits anyplace a pallet can match…like in a 45-foot trailer, as an illustration. Graced with a robust, long-life battery “Stretch [can work] by an eight-hour shift, or as much as 16 hours with the prolonged vary choice.”

Boston Dynamics VP of Product Engineering Kevin Blankespoor envisages Stretch’s typical day going one thing like this: “Stretch may spend the morning on the inbound aspect of the warehouse, unloading packing containers from vans. It’d spend the afternoon within the aisles of the warehouse, increase pallets—these will go off to retailers or e-commerce facilities. And it would spend the night loading packing containers again into vans.”

![]()

[ad_2]