Texture Primarily based, Full Coloration 3D Printing: 5 Issues to Contemplate

Upon the appearance of 3D printing, novelty revolved across the concept of making a 3D file and changing that right into a 3D printed product made layer by layer. Initially supposed as a device for engineers to carry out fast prototyping and enhance product improvement behind the scenes, mainstream firms and organizations quickly realized the numerous advantages concerned, starting with the power to iterate effectively.

Bridging the Gaps Between Primary and Full Coloration 3D Printing

At present, the valued partnership between Shapeways and Mimaki is a extremely complementary one with the 2 firms main as respective veterans in 3D printing and the appliance of full coloration. Whereas industrial producers depend on the expertise for fast prototyping and manufacturing of high-performance elements, coloration 3D printing capabilities have expanded use in purposes like gaming too. Tabletop gaming miniatures could be personalized with unimaginable element for bringing journey characters to life. There’s no have to accept elements in fundamental white or grey anymore although both –particularly when you may stay up for 3D printing supplies like Excessive Definition Full Coloration with over ten million hues out there.

Utilized in mixture with Materials Jetting expertise, 3D printed elements are literally white and clear within the center, with the colour utilized simply across the outdoors edges.

“If you happen to have been to take one in every of our coloration prints and reduce it in half, what you’ll see is a mixture of white and clear within the heart, with coloration on the surface edge; nonetheless, that coloration on the surface is pigmented resin, so it’s the similar bodily properties as what’s constructing the construction,” says Josh Hope, Sr. Supervisor, Digital Imaging & Innovation at Mimaki. “We aren’t jetting white after which coloring it—we are literally jetting pigmented resin.”

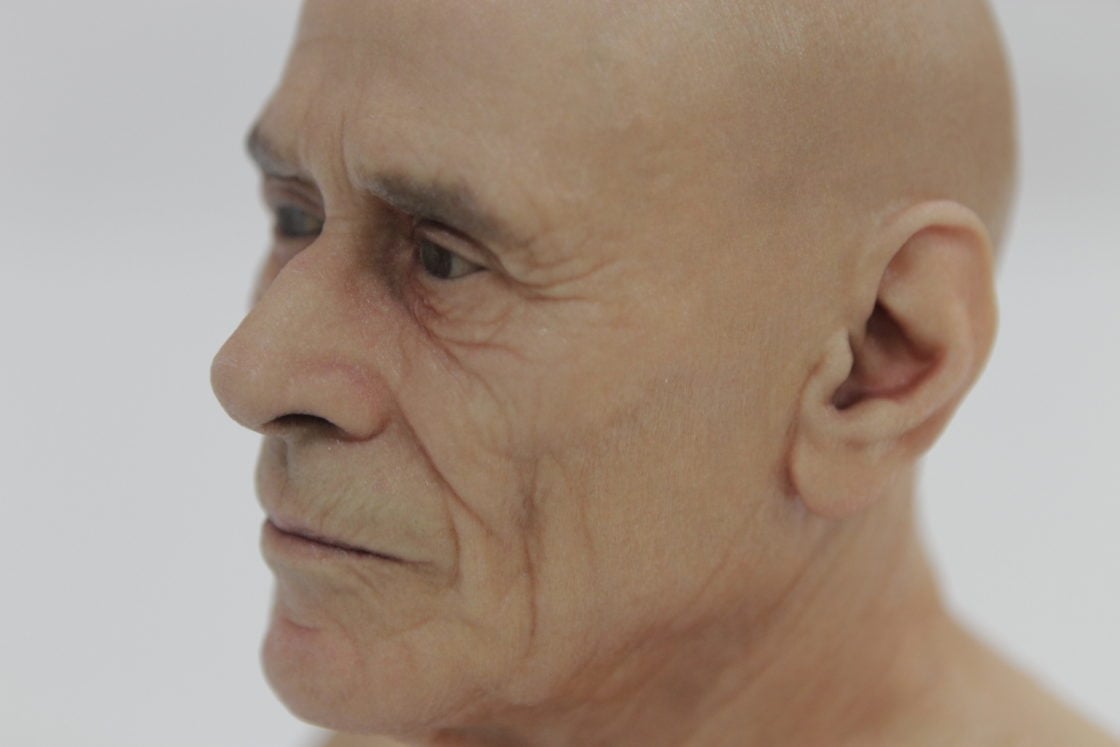

Whereas even probably the most fundamental components of 3D printing open the door to numerous alternatives for innovation, full coloration 3D printing elevates that course of to the following stage with nice element for modeling, glorious accuracy and backbone in 3D printing, and unprecedented photorealism within the completed product. Engineers depend on full coloration for 3D printing in a number of industries, designing for purposes like medical modeling for surgical prep, or structure, presenting intensely detailed fashions for brand spanking new developments and accompanying infrastructure.

Clear 3D Fashions Result in High quality 3D Printed Elements

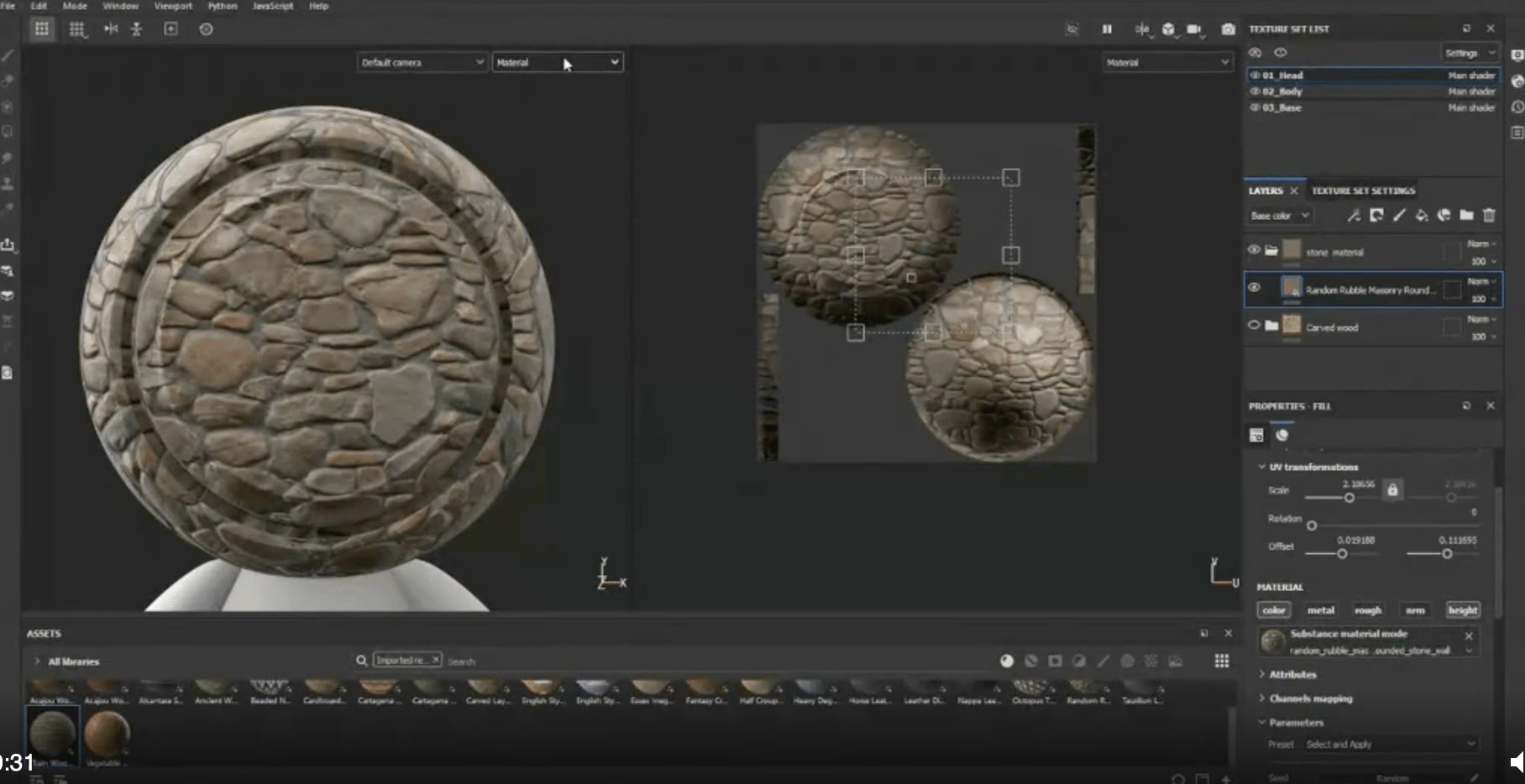

Step one is to work with a modeling software program that provides as many instruments as attainable on one platform. Whereas Mimaki 3D Functions Specialist Jaime Martinez used free, open-source modeling software program like Blender for example whereas co-presenting the current webinar with Shapeways, there are a lot of completely different merchandise on the market, relying on a designer’s desire and undertaking scope. Subsequent, it’s crucial for any designer not solely to outline precisely what it’s they’re hoping to 3D print, however to even have a full understanding of all of the modeling instruments with which they’re working.

Creating a high quality design and 3D mannequin is an integral a part of the product improvement course of, counting on an understanding of transfer completely different mesh designs, together with utilizing the extruding and scaling instruments.

“As your expertise grows in modifying and adjusting your wants for a mannequin, you should have extra management of your mesh,” mentioned Martinez. “It doesn’t matter what sort of undertaking you might be designing for, nonetheless, a clear mesh is at all times simpler to edit.”

Martinez goes on to emphasize the significance of honing 3D modeling abilities over the concept of attempting to re-work downloaded fashions. Whereas this can be a typical temptation, he factors out that it isn’t really useful regardless of the supply of instruments meant for drawing over present mesh.

“There’s no silver bullet for cleansing up downloaded geometries. Some automated instruments can work properly, however the very best avenue is absolutely simply to get higher at modeling. Whereas we could take pleasure in having all the pieces automated, human enter remains to be essential for particular particulars within the 3D mannequin and 3D printing elements,” mentioned Martinez. “People are nonetheless very related to this course of.”

Continued studying in regards to the technique of modeling results in mastery in creating shapes, or mesh, all a group of elements which end in viable 3D buildings for prototypes or useful, end-use elements. After that, the remaining falls into place simply, with fundamental mesh simply was a formidable remaining construction.

Working with Texture

Using texturing performs a tremendously necessary position for a lot of 3D printing initiatives that embrace coloration. Whereas this characteristic could also be used merely to reinforce the look of a mannequin, 3D texture will also be utilized to cover imperfections like layer strains and in the end, present several types of shading.

Texture maps start with base coloration, permitting for the choice so as to add a big selection of particulars that may be manipulated, usually giving merchandise a extra genuine look relying on desire and undertaking necessities.

“We normally add particulars utilizing a black and white picture referred to as a displacement map,” mentioned Martinez. “The black and white picture both lifts or lowers the mesh floor. You need to use that to your benefit in including particulars to your mesh, testing the scale of the map and particulars at first.”

“Results are utilized as soon as you might be proud of all of the elements of your mesh.”

Including full coloration and texture to a 3D print result in a mix that’s not solely highly effective by way of aesthetics but in addition for imbuing elements with better energy. Texture-based workflows are enjoyable for designing smaller items like tabletop gaming characters–permitting for superb particulars, patterns, and enhanced options–however will also be extraordinarily useful in industrial settings for high-performance elements constituted of a variety of supplies. It’s also attainable to color coloration proper right into a texture through the modeling course of.

Design for Helps

For full coloration 3D printing with Mimaki, helps are required to stabilize elements throughout printing. Help buildings assist connect elements to the print mattress, reducing the potential for deformation, and making certain a greater consequence general.

In designing helps for Excessive Definition Full Coloration with Materials Jetting, each overhang might be projected towards the underside, requiring a flat floor for the ink, or materials, to ‘land’ on. When helps are required, some geometries can inevitably be tough; nonetheless, with correct orientation it’s attainable to chop down on the extreme use of such buildings.

Hole 3D Printed Merchandise to Decrease Weight and Price

Hollowing can signify important financial savings in materials, time, and energy expended in 3D printing, however the designer may additionally have to find out whether or not the advantages outweigh the potential for issues by way of eroding energy of the half, affecting the floor end, and requiring particular necessities for overhangs in some circumstances.

“If you happen to hole your half, it could be essential to incorporate drains or perforations to ensure you can take away the helps,” mentioned Martinez.

Ultimately, the choice on whether or not or to not hole out a design usually is dependent upon the size of the design.

Discover Shapeways Assets on Full Coloration 3D Printing

Be taught much more in regards to the significance of full coloration in 3D printing in the present day by watching a replay of the webinar, ‘File Preparation for Texture Primarily based Full Coloration 3D Printing’ right here. Co-presented by Shapeways and Mimaki, viewers can observe the second webinar targeted on full coloration however extra particularly, on advancing ahead to 3D file preparation and extra superior choices and methods–as associated to manufacturing for the Mimaki 3DUJ-553 and the compact Mimaki 3DUJ-2207.

A powerful quantity of element and coloration gradients could be achieved with Excessive Definition Full Coloration, accentuated with the subjects mentioned within the webinar. Full-color 3D fashions can be found in both a regular or matte end. Remaining elements could be coated, and hardware-like screws could be simply connected for hanging necessities or different preferences.

About Shapeways

Get pleasure from the advantages of this superior expertise and a variety of supplies from Shapeways for 3D printing your creations with accuracy, advanced element, and no minimal or limits by way of mass customization or single half orders. Shapeways has labored with over 1 million prospects in 160 international locations to 3D print over 21 million elements! Examine case research, discover out extra about Shapeways additive manufacturing options, and get immediate quotes right here